chemical decarbonation / Catalytic Carbonate Removal – Softazur® C

Softazur® C (formerly known as Gyrazur) is a fluidized bed upflow reactor designed for catalytic carbonate removal. In this process, the decarbonation of hard water (>30°F) is achieved through chemical precipitation on a bed of calcium carbonate pellets.

This process is particularly suitable for raw water with high hardness and low organic matter content and is ideal for applications of high production rates. It can be used with either lime slurry (lower reaction kinetics) or liquid caustic soda (faster reaction kinetics).

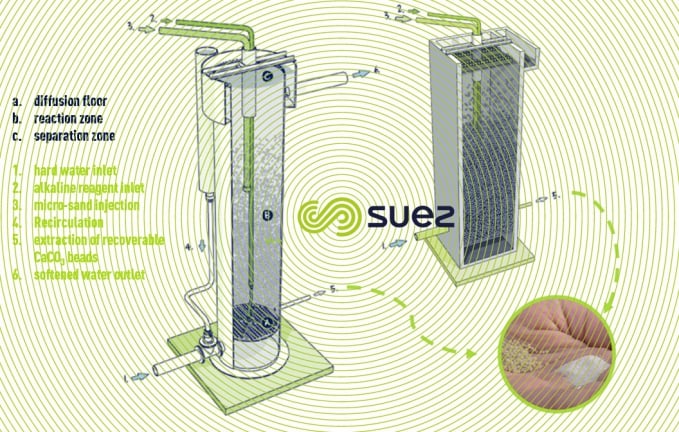

Softazur ® C consists of three parts: a water diffusion floor, reaction zone, separation zone.

Construction options: circular metal structure or square concrete structure

Softazur ® C is used for:

- Partial or total carbonate removal

- Elimination of Nickel and most alkaline earth metals at high pH

key figure

- High speed: 80 to 100 m/h

among our references

- Chen Chin Lake (Taiwan), 18,000 m3/h

- Aubergenville – Flins (France) 4,920 m3/h - 118,080 m³/d – (concrete)

- Le Pecq (France) 2,500 m3/h -60,000 m³/d – (concrete)

- Saosnes Bel Air (France) 230 m3/h - 5,520 m³/d – (metallic)

- Compactness: its low footprint allows easy integration into existing factories.

- Simple maintenance: only a few valves and a recirculation pump as mechanical equipment

- Performance of the process: allows complete separation of the precipitate with a very high upflow velocity.

- Obtaining a solid residue: generates limestone balls (diameter 1 to 2 mm) ready for immediate recovery without prior dewatering

- No dedicated sludge treatment line

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later