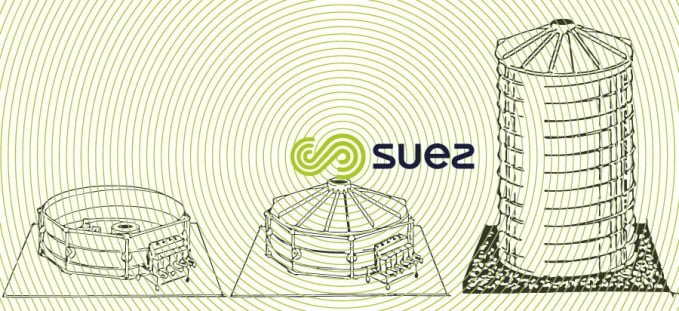

metal digester - Digelis Simplex - video

The Digelis® Simplex technology is based on a seamless, bolt-free construction method applicable to mesophilic and thermophilic digesters with or without integrated gasometers, with capacities of up to 7,000 m³ per structure.

The construction of the reactor is carried out directly on site on concrete slab foundation by rolling around a circular structure of stainless steel Verinox strips. To ensure sealing the reactor, the steel strips are joined by folding (Double Seam Lipp system). This method of quick and effective construction is comparable to an advancing screw: as every round completed, the reactor rises and takes shape. It has been implemented by our partner for over 50 years.

The sludge mixing inside the reactor requires minimal energy.

key figure

- more than 1,000 units built with this method

among references

- Boneo (Australia) – 2 x 2 ,500 m3

- Panama city : 1 x 5,000 m3

- Roanne (France) : 2 x 3,100 m3

- Mulhouse, Sausheim (France) : 1 x 5,100 m3

video presentation

- Reduced construction duration thanks to on-site reactor design

- Durability: maximum strength and watertightness

- Sludge heating system without the need for an external heat exchanger

- Modularity and ease of operation

- Safety: mechanical mixing does not require a biogas compressor, thereby reducing the constraints associated with ATEX standards.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later