Sequencing Batch Reactor (SBR) with densified sludge – Cyclor® Turbo - video

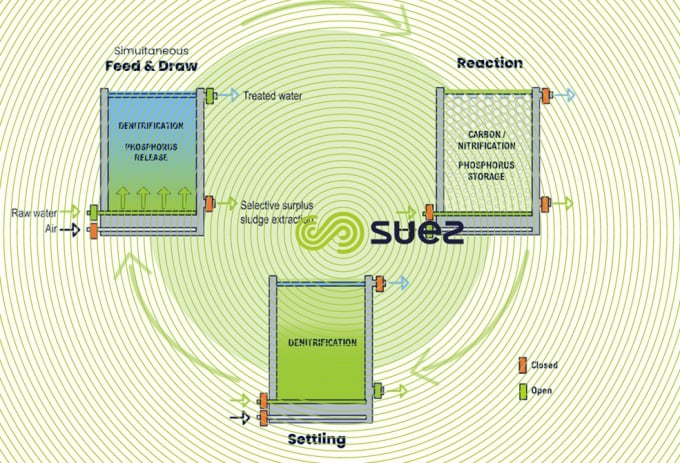

The raw water is fed under anaerobic conditions into the sludge bed, while the treated water is simultaneously withdrawn from the upper part of the reactor using a patented fixed-level sealed system. The system operates at a constant water level.

Key figures

- Up to 40% footprint reduction compared to conventional SBR

- Up to 50% footprint reduction compared to Conventional Activated Sludge

- TSS < 15 mg/L (less than Conventional Activated Sludge)

Among our references

- Central Manila (Philippines), 180,000 m3/d - 800,000 PE (Greenfield)

- La Roche-sur-Yon (France), 26,000 m3/d - 120,000 PE (Greenfield)

- Changsu Binjiang (China), 8,000 m3/d, 20,000 PE (Brownfield)

- Full-scale demonstration facility (800 m3/d) at East St Paul, Manitoba (North America) by NEXOM (licensing partner).

video presentation

- Robust & Resilient: The quality of treated water is stabilized regardless of climatic conditions or operational variations

- High compactness due to its improved settling properties(Sludge settling velocity up to 4 times higher in comparison with conventional activated sludge)

- Sustainable: Phosphorus removal without chemical reagents and electrical cost savings

- Efficient: better denitrification and improvement of biological phosphate removal

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later