ultra dewatering - Dehydris® Ultra

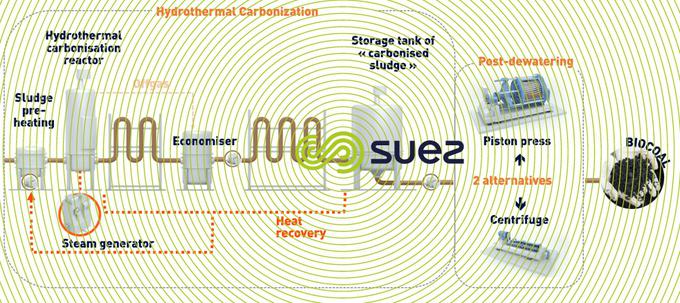

The ultra-dewatering workshop Dehydris® Ultra combines hydrothermal conditioning and post-dewatering to produce a sanitized biocoal that is easily transportable and storable. This process mimics the hydrothermal carbonization of the organic matter contained in sludge, in a thermal conditioning reactor operating between 175°C and 220°C at low pressure (< 30 bar).

The ultra-dewatering workshop can be configured with either a centrifugal decanter or a piston press for post-dewatering.

- With piston Press: Achieves 60–65% dryness without chemical conditioning for most sludge types, reducing sludge volume by up to 75%, cutting storage and transport costs (4x fewer trucks).

- With centrifuge: Achieves 40–45% dryness. It reduces sludge volume by up to 60%, requiring 2.5x fewer trucks.

key figures

- Up to 75% cake volume reduction compared to conventional dewatering solution

- Up to 70% carbon retained in the Biocal

among our references

- Pau Lescar (France) 200,000PE

- Production of a hygienized and valorisable Biocoal

- Technology achieving thermal energy self-sufficiency through coupling with digestion

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later