static mixers

Reading time:Static mixers are machines mounted direct in the pipeline or open channel.

static mixers mounted in pipelines

Static mixers mounted in pipelines have a very high velocity gradient (1,000 to 30,000 s–1) and very short contact times. The energy dissipated is equivalent to their head loss. Therefore, the performance of these units decreases as the true flow rate becomes markedly lower than the nominal flow rate. Furthermore, the quality of the mix will depend on the design of these units.

the simple mixer with injection pipe

This system normally comprises an injection pipe followed by a diaphragm and is used to inject reagents that are easy to mix. Standard models are available for 100 to 400 mm diameter pipes. Head loss will be equal to at least 0.3 m of WC. The mixing operation takes place over a considerable length that is usually equivalent to 50 to 100 times the diameter of the pipeline, depending on the implementation mode.

the packing mixer

This system is used to inject mineral reagents and polymers. Packing usually consists of vanes, lamella or reverse pitch screws. Their pressure drop also ranges from 1 to 5 m of head. This system is used to inject concentrated solutions having an output that only represents 0.01% of the raw water flow rate. The mixing will have been fully completed at the mixer outlet after travelling a distance equivalent to 2 to 6 times the diameter of the pipeline.

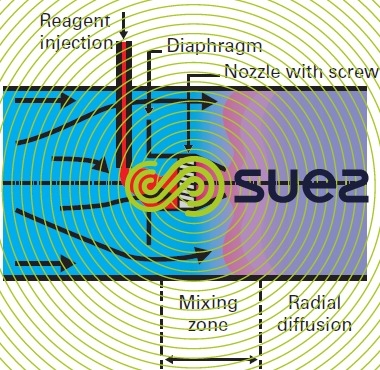

the radialmix radial mixer

This is a hydraulic radial diffusion mixer used to inject mineral reagents, polymers… It comprises a nozzle centred along the pipeline's axis and a plate with peripheral apertures (figure 2).

Standard models are available for 100 to 400 mm diameter pipes. Head loss will range from 0.2 to 5 m of WC depending on the models and on applications. This system is used to inject concentrated solutions having very low outputs (up to 0.0005% of the raw water flow rate). The mixing operation takes place entirely over a length that is less than the diameter of the pipeline.

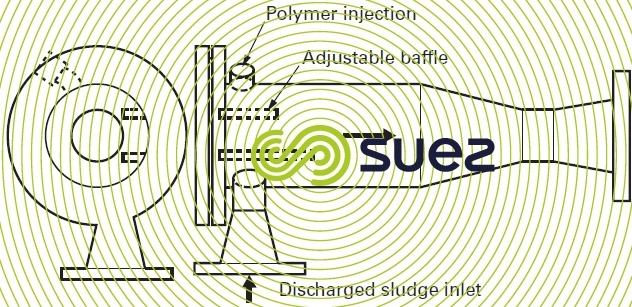

the MSC sludge mixer

This cyclonic type mixer is ideal for sludge conditioning (figure 3). It comprises a cylindrical section which receives incoming sludge and the reagents, followed by a conical section in which thorough mixing takes place in a spinning motion. The cylindrical section comprises two adjustable baffles.

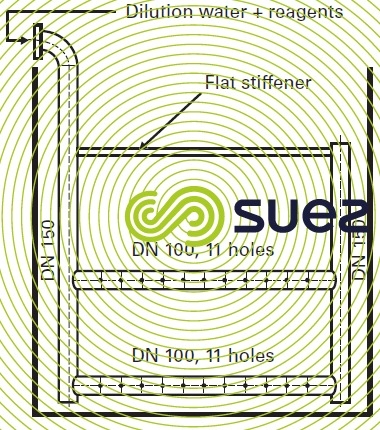

channel mounted static mixer

When the mixture circulates through a channel, insufficient energy is imparted to the mixture as head loss. In order to rectify this situation, the channel mounted static mixer uses pressurised dilution water at a flow rate that represents 2 to 10% of the raw water flow rate.

As a rule, this unit will be of the «pipe or simple screen» type where the dilution water intended to create the reagent diffusion outlet velocity is mixed with the reagent a few metres upstream from its injection into the unit (figure 4).

Head loss in the injection loop will range from 2 to 10 m of WC. This mechanism is used to inject concentrated solutions. The mixture is entirely completed within 10 to 20 seconds.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later