generalities

Reading time:Thermal processes used to destroy the organic matter contained in sludge vary widely. We have restricted ourselves to a description of the most frequent state of the art system.

Various methods can be devised to classify processes; indeed, their names are legion and this proliferation is linked to both marked technical differences and also to orientations that have more to do with industrial marketing.

We believe that the first classification has to highlight the concept of pressure which distinguishes pressure destruction processes from atmospheric pressure processes.

In this chapter, we are deliberately leaving pressurised gasification to one side as it is not specifically and exclusively applied to sludge. There are a few rare instances of combined treatments (with other waste). Wet oxidation will be the only pressurised process discussed here (see section organic matter destruction using the wet oxidation method).

Atmospheric pressure processes are all derived from the principle whereby the bonds that form organic matter are destroyed by the effect of increases in temperature and of the partial pressure of free O2. When this partial pressure of free O2 is high and in the region of 6%, reflecting excess air in the region of 40%, we enter into the field of traditional incineration that may be dedicated (conditions specific to sludge) or combined with other products (such as co-incineration with household waste, with special industrial waste (DIS in French), and in cement plants and power stations).

When this O2 partial pressure is virtually zero, we enter into the field of gasification processes which, depending on how this gasification takes place, will be termed pyrolysis or thermolysis (see section pyrolysis and thermolysis applied to sludge). These processes do not oxidise organic matter but "crack" it, producing reducing gases (termed syngas): CO, CH4, Cn Hm…

Furthermore, the distribution of pollutants (heavy metals, NOx) will vary from phase to phase according to temperature profiles.

Technologies that are specific to incineration or to thermal decomposition have been known and applied for decades by different industries. They can be briefly described according to the technology used for their main reactor (furnace).

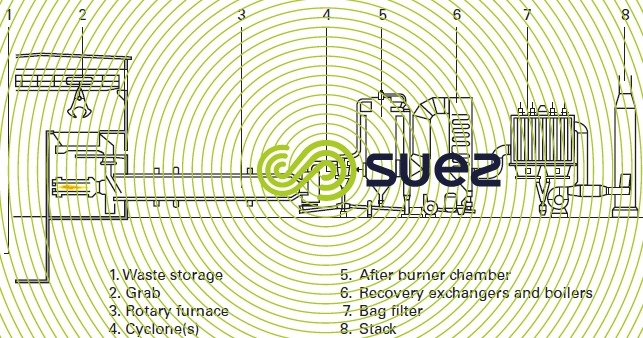

rotary furnace (figure 25)

This is a rotating drum that is lined with firebricks and usually followed by a vertical post-combustion chamber in waste processing applications. The best known furnace in this range is the cement works furnace; it is also used for producing lime. Its simple process has been extended to waste treatment and, more specifically, to heterogeneous and/or special waste where post-combustion is compulsory in order to achieve perfect combustion and statutory temperature levels. This system is not widely applied to processing sludge produced by a wastewater treatment plant because of the problems associated with excess air control (having an impact on the heat balance) and of the high viscosity zone covered in the chapter on drying, this zone inducing agglomeration phenomena responsible for a high level of disturbance.

grate kiln

This kiln is quoted as a reminder because it is used exclusively for household waste. It should be noted that sludge can be co-incinerated either in its pre-dried form (see section sludge drying to an intermediate dry solids content) or in its simple dewatered form (see IC 850 process in the section organic matter destruction treatment using co-incineration processes).

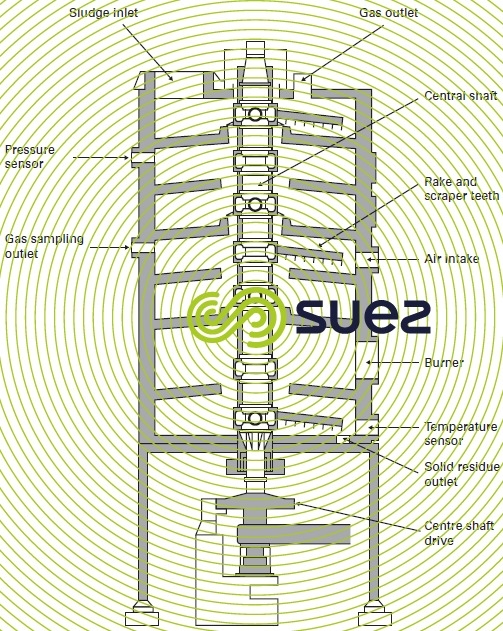

multiple hearth (figure 26) furnace

This incinerator is over one hundred years old and was widely used in the USA during the 60’s for direct incineration of wastewater treatment plant sludge. It became widely used in Europe, especially in France; its development was then slowed down by the successive oil crises. Some are still in operation to this day with integrated post-combustion (Bologna).

This technology is now resurfacing in the sludge field, no longer for direct incineration but rather for more sophisticated gasification systems (see section pyrolysis and thermolysis applied to sludge).

fluidised bed incinerator

This is also an incinerator that goes back a long way: it first saw the light of day in coal gasification applications but underwent major development in the ore roasting field. The Dorr Oliver company was one of the main developers of this technology. When sludge incineration emerged during the 70’s in Europe, it rapidly gained ascendancy and, nowadays, it is the most widely used direct incineration technique applied to dewatered sludge. There are many existing systems in operation.

Within the dedicated incineration context, we shall confine our attention to this technology in the following.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later