Methane fermentation

Methane fermentation has been used for more than a century ago in the treatment of sewage sludge at wastewater treatment plants. Effectively, this method helps to reduce sludge volatile content and, consequently its mass; due to its mixing characteristics (15-20 days of mixing in digester), the methane fermentation process also offers sludge homogenisation, which is necessary for effective sludge dewatering at minimum energy requirement. The energy generated by biogas production offsets the energy required for heating and mixing in the digester.

These features of methane fermentation (see Anaerobic bacterial cultures), mainly its BOD reduction at low energy requirement and at minimum sludge production result in the extension of its application to the treatment of industrial wastewater (IWW) containing high levels of dissolved organics.

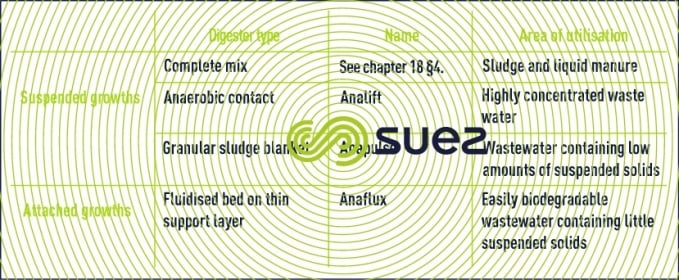

Over the past 30 years, various technologies have been developed by SUEZ, including techniques by suspended growth or by attached growth, (Table 1). These equipments are known as either digesters or methane fermentation units.

This chapter only addresses methane fermentation of the effluent; sludge digestion is discussed in liquid sludge stabilisation.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later