Meistratzheim wastewater treatment plant (France)

A model plant in recovering the potential energy from industrial effluent and sludge.

With the two existing plants treating wastewater from the Ehn water basin having become obsolete, the SIVOM (Syndicat Intercommunal à Vocations Multiples) decided to replace them with a new wastewater plant located in the town of Meistratzheim.

With a 240,500 population-equivalent capacity, this plant, built by SUEZ, treats the wastewater from 11 towns located in the Terres de Saint Odile area (i.e. 24,000 inhabitants) and the effluent of local sauerkraut manufacturing plants (i.e. the equivalent wastewater of 140,000 in habitants at peak flow).

pretreatment :

This first phase consist in removing the solids contained in the effluent. Paper, plastic, leaves, etc. are retained by screens made from sufficiently fine mesh. Water is then removed from the residue which is then compacted with household waste before disposal. The removed water is treated in a treatment plant.

Grease and grit are also removed from the effluent thanks to a grease trap units. The fats, less dense than water, are recovered by raking the surface of the unit. They are then used for producing energy on site.

Grit, denser than water, settles to the bottom of the unit. It is removed and washed. It may be recovered for use as backfill, for example. The water used for washing is treated at the plant.

biological treatment of activated sludge :

Biological treatment calls upon a wide variety of micro-organisms, mainly bacteria. By absorbing soluble and suspended constituents contained in wastewater, these micro-organisms convert biodegradable organic matter into simple products such as carbon dioxide and additional biomass, or nitrate and gaseous nitrogen when the conditions for this occur.

"Activated sludge" biological treatment is comprised of a reactor (biological tank = aeration tank) in which micro-organisms responsible for purification are cultured. A clarification tank then separates the purified water and the biomass. The biomass naturally settles and clear water is collected at the surface. The latter is then polished via a tertiary treatment.

Part of the settled sludge from the clarifying tanks is recirculated in the aeration tank. Excess sludge is sent to a sludge treatment process.

tertiary treatment : tertiary filtration using Filtrazur

Filtrazur filtration is a polishing treatment. This filter's special feature lies in the use of a filtering medium whose density is lower than that of water. The medium is made up of expanded polystyrene beads ensuring that the residual particles of pollution are well fixed. The condition of medium's surface encourages the fixation of nitrifying bacteria. Filtrazur can further remove ammonium, depending upon the dissolved oxygen present in the water.

Upon completion of this tertiary filtration operation, the purified water can be discharged into the Ehn.

sludge treatment process

- Fenced thickening of primary sludge;

- Mechanical thickening of secondary sludge;

- Anaerobic digestion of mixed sludge;

- Centrifuge dewatering of digested sludge:

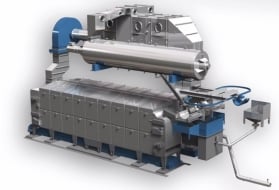

- Thermal drying of dewatered sludge with an INNODRY 2E dryer.

air treatment process

- Physico-chemical odour removal using 2 towers: acid and soda/bleach.

treating sauerkraut juices

Sauerkraut juices are acid and hot (65°C) and contain large quantities of carbonated compounds (i.e. the equivalent wastewater of 140,000 inhabitants at peak flow), salts and fats. Fats are recovered for on-site energy production. The particular composition of sauerkraut juices requires specific treatment which is different to that of standard urban wastewater. The particularity of their treatment lies in the possibility to produce energy within the plant.

Pretreatment: When the juices arrive at the plant, they are poured into 2 x 100 m3 watertight tanks. The fine suspended matter is screened out. A flotation tank then makes removing the fats from the surface of the tank easier. As the juices are acid and if necessary, the pH is adjusted by adding soda.

Anaerobic digestion: the high concentration of dissolved organic matter in the sauerkraut juices is treated by methane fermentation. The Biopaq IC process contributes to the reduction of volatile matter and consequently the reduction in the volume and mass of the juices.

In the absence of air, specific bacteria are mixed with the sauerkraut juices. Bacteria transform most of the organic compounds into methane and carbon dioxide. This biogas is separated from the liquid phase and can be used to produce energy. The treated sauerkraut juices constitute a residual liquid effluent which is then mixed with the urban wastewater entering the plant and then undergoes standard treatment.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later