measurements principles applicable to routine parameters

Reading time:flow measurements

Of the most commonly used parameters, flow measurement must be monitored with the greatest care because it is this parameter that will serve as the basis for all regulation and control.

Depending on whether we are dealing with clean or with waste water applications and depending on whether the flow is open to the atmosphere or through a pipeline, there are a range of instruments based on various principles that we can use to measure this flow.

The use of flowmeters makes a few mandatory rules:

- irrespective of the flow measurement principle used, there needs to be care taken with respect to installation conditions that are specific to the technology used;

- when required to measure flow at the plant inlet and at the plant outlet, the same measurement principles must be used at each point in order to avoid measurement discrepancies between upstream and downstream.

There are various areas: open channel, pipeline and gas-specific measurements.

open channel flow measurements

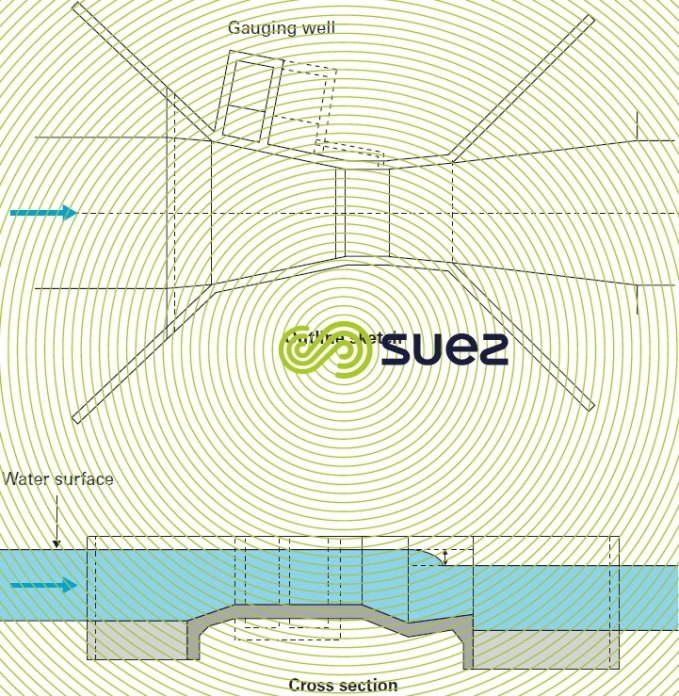

Flow measurement often consists of routing the flow through a device that creates a head loss (venturi, weir, measuring sill, Parshall Flume) and measuring the height of the water surface upstream from the device (using a US sensor, a piezometric sensor or a bubbler tube).

Venturis are most frequently used when major flows are involved; the Parshall Flume (figure 1) venturi is also often selected for flows in excess of 5,000 m3·h–1 in order to minimise head losses through the hydraulic gradient.

(Non-standardised) flow measurement through an open channel free of any restrictions can, however, be undertaken by combining the average flow rate (radar or US) and the water depth in the channel (US). However, in this case, the measurement obtained is less accurate.

flow measurements through pipelines

Depending on quality, the conditions applicable to the fluid to be measured and the flow range, we can select one of the following principles:

- electromagnetic flowmeter with sleeve or, occasionally, an inserted probe; this system is becoming more widely used, even on liquid and paste-like sludge;

- transit time ultrasonic flowmeter;

- differential pressure flowmeter (aperture plate, Pitot tube, venturi, Vcone); for use exclusively on no-load fluids;

- turbine flowmeter, rotary vane flowmeter;

- Doppler effect flowmeter;

- target flowmeter;

- floating indicator or "all metal" flowmeter (e.g. on thermal oils).

flow measurement on gases

There is increasingly use of heat mass flowmeter technology (air, biogas) and of the vortex velocity flowmeter (vapor).

level measurements

Depending on whether the instrument is to be used on liquids, solids or powders, we have a range of different principles for performing these measurements. We need to choose from the following principles: ultrasonics, radar, wire-guided radar (ash or activated carbon stored in silos), capacitative sensor, pressure sensor (hydrostatic level) or weighing.

Differential measurement using ultrasonics or piezometric systems is often used to monitor bar screen fouling.

pressure measurements

Depending on the fluids to be monitored, on loaded products, we use the flushmounted membrane measurement principle instead of the separator.

differential pressure measurements

Differential pressure applications require comprehensively defined installation and service conditions.

temperature measurements

For temperature measurement, the thermo-electric principle applies with PT100 resistor probes (100°C platinum resistor) for applications ranging from -50°C up to 300/400 °C. Beyond these temperatures, the thermocouple technology (two-metal pair) applies.

stress, mechanical torque measurements

These measurements are used for some rotary electromechanical units in order to safeguard them from abnormal stress.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later