powdered activated carbon (PAC)

Reading time:

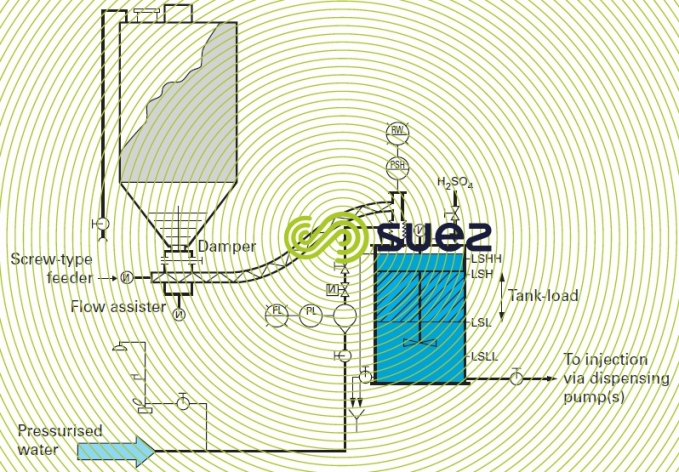

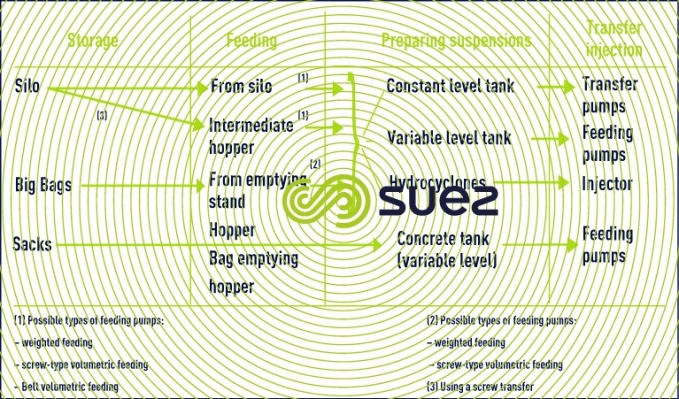

Depending on the size of the plant, PAC can be stocked in sacks, in silos or in big-bags and table 2 shows the various systems that can be used to produce a suspension often called a "slurry" containing 30 to 50 g · L–1 of PAC.

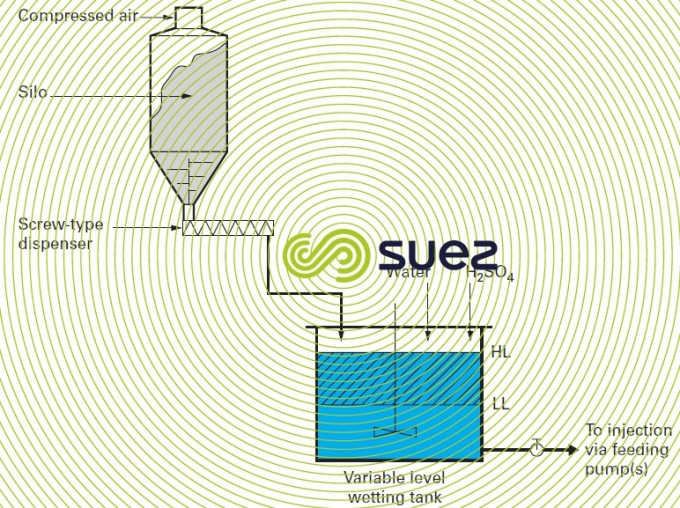

In large plants (figure 23), the screw feeds the wetting-acidification tank direct; therefore, in order to obtain a precise slurry concentration, it is essential that a precise volume of water be used as well as an amount of carbon measured by volume (or even better, a weighted amount).

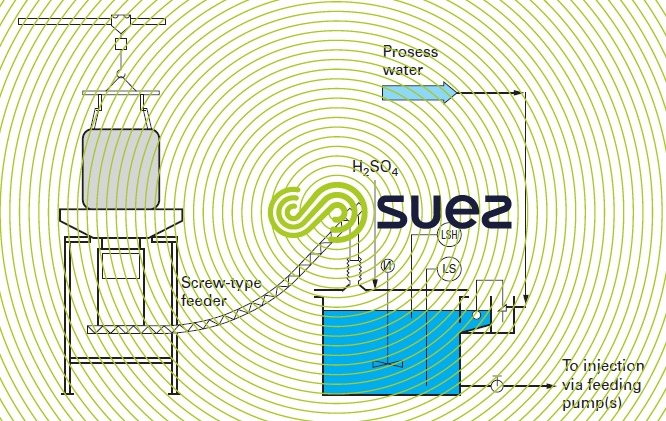

With tall silos where the PAC tends to compact, it is advisable to insert an intermediate decompaction hopper to ensure accurate volumetric feeding.

Activated carbon can be decompacted by installing an "intermediate hopper". A transfer screw or a rotary vane feeder feeds the hopper. The feeding system is mounted on the “intermediate hopper”. Once the PAC has been decompacted, a volumetric feeding (screw-type feeder) then becomes feasible.

PAC is a product having a widely varying density that depends on its level of fluidisation or compaction (200 to 600 kg · m–3). This fluctuating density causes risks of creep, or mounding, both of which must be prevented.

Furthermore, PAC is a base product. It contains oxides such as CaO which, when wetted, forms Ca(OH)2, creating carbonation in the injection pipes. Therefore, the wetting water must absolutely be acidified whenever it has a TAC > 5 °F.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later