lime

Reading time:Lime is the most widely used reagent in water treatment applications. It is supplied in two forms:

- quick lime: CaO;

- slaked (or hydrated) lime: Ca(OH)2.

Warning: in both cases, these reagents will contain between 4 and 20% of solid impurities (CaCO3, SiO2…). These impurities must be removed before the product is used.

quick lime

slaking quick lime

Quick lime is used in water treatment and mainly as a powder. It has the following advantages over slaked lime:

- less expensive;

- greater CaO content than slaked lime, higher apparent density, resulting in lower transport and storage costs (quick lime: apparent density: 0.7 to 1.2, slaked lime: apparent density: 0.3 to 0.6).

However, quick lime does have two drawbacks:

- additional investment in order to guarantee a proper level of slaking;

- quick lime quality is often far more variable than that of slaked lime.

The following reaction applies to the slaking of quick lime:

This is an exothermic reaction and the heat released at 25°C will be 275 kcal per kg CaO (see characteristics solution constants).

The chemical reactivity of lime slurry along with the fineness of the suspension will depend on the slaking temperature. This temperature must be as high as possible and, therefore, involve a minimum amount of added water.

quick lime in powder form

Quick lime used in water and sludge treatment usually satisfies the following specifications:

- content:

- CaO > 90 %,

- MgO < 1.5 %,

- SiO2 < 1.5 %;

- reactivity with water: less than 25 minutes to reach 60°C for a mixture comprising 150 g lime/600 g water and a starting temperature of 20°C;

- fine or sieved lime (0-90 mm particle size).

In practice, two types of preparation are used:

- paste slaking (with high mixing energy): three to four parts water are mixed with one part lime producing maximum temperature increase and short slaking time. The amount of water used will depend on the paste’s viscosity (mixer torque) and/or temperature;

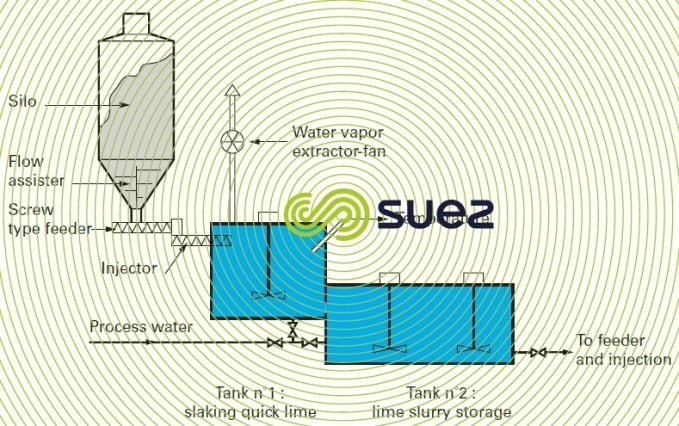

- suspension slaking: the target lime slurry Ca(OH)2 concentration ranges from 50 to 200 g · L–1 ; the temperature probe is used as a safety measure on the lime inlet. This type of installation (figure 10), although less efficient, can be automated more easily and more simply, thus reducing operating, safety and maintenance requirements.

Attention : never switch off mixers in tanks n° 1 and 2 when they still contain lime slurry as the lime will settle and solidify.

quick lime granules (0-20 mm)

A paste slaker can be used when it includes a fixed horizontal trough slaking chamber with a blade mixing system and a dilution chamber and mechanical removal of impurities.

crystal lime (10-60 mm)

We can use:

- a large capacity continuous system (1-10 t · h–1) comprise of:

- a slow rotation horizontal cylindrical drum equipped with mixing blades and lime lifting baskets and primary separation;

- a purifier with mechanical impurity extractor;

- a small capacity batch system (1-2 t · d–1), a sturdy appliance for crushing rocks using mallets or suspended scraper blades.

producing lime slurry from quick lime

Slaked lime is usually used as a lime slurry, an aqueous suspension of calcium hydroxide particles. Its concentration is usually between 50 and 100 g.L-1 for ease of use; in effect:

- for C > 100 g · L–1 : danger of deposits and blockages;

- for C < 50 g ·L–1 : danger of carbonation.

storing lime powder

Powdered lime is stored in 25 kg bags or in a silo, depending on the size of the installation. In France, the preferred minimum silo capacity is 50 m³, this being the maximum lorry payload (25 tonnes).

The base of the silos is equipped with a flow assister. Mechanical flow assisters are usually preferred over fluidisation air injection systems.

transferring powdered lime

By order of preference, lime powder can be transferred:

- by gravity (whenever possible);

- mechanically (usually by means of a screw);

- pneumatically (over short distances, for instance when unloading tanker trucks).

dispensing

- Lime powder

The quantity of powdered lime delivered to dilution tanks is metered out either using volumetric feeders (rotary vane or screw feeders) or gravimetric feeders (weighing hoppers).

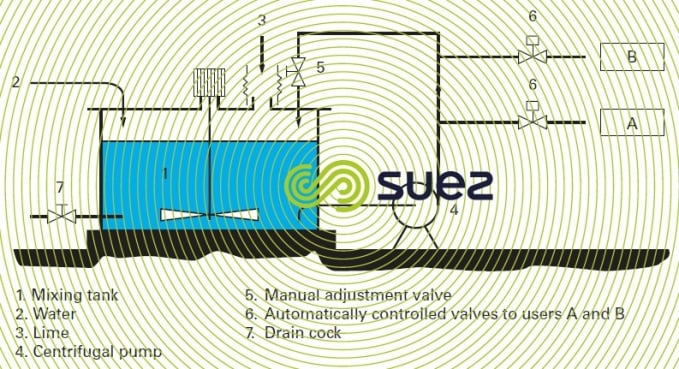

- Lime slurry

Lime slurry is prepared at a virtually constant concentration in dilution tanks with mechanical agitation such as those featured in figures 7 or 8, from water of moderate calcium carbonate alkalinity (scale forming).

The slurry is delivered by pumps:

- positive displacement pumps (dispensing or eccentric rotor pumps);

- centrifuges, preferably dispensing a distribution loop equipped with automatic injection valves operated in "on/off" mode (figure 11). In this case, feed is often regulated by the opening frequency of these valves, e.g. based on the information supplied by a pH meter.

special operating instructions (clogging)

As lime slurry is a particle suspension of particles, these particles are likely to settle as soon as agitation or circulation systems are switched off: the ensuing deposits can jam mechanical units, e.g. pressure relief valves, valves, feeding pumps … Therefore, lime slurry calls for compliance with special precautions in connection with the construction and operation of preparation and dispensing units. E.g.:

- using pipes made of flexible materials (rubber) or that can easily be dismantled;

- pipe diameters providing a compromise between:

- an adequate passage section (blockages);

- an appropriate circulation velocity (deposits);

- using clean water to flush through after each shutdown.

lime water

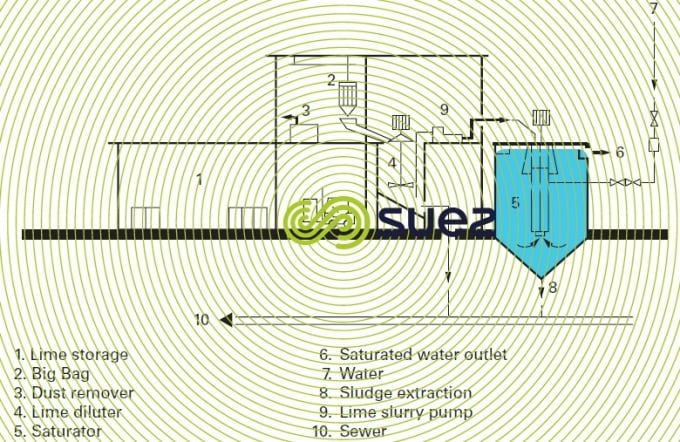

Lime water (lime saturated solution) is often used in drinking water plants. Its titer, depending on dissolution temperature, will be approximately 220°F of TAC at 20°C, This is equivalent to a 220 × 7.4 mg · L–1 concentration of Ca(OH)2, i.e. 1.6 g · L–1 (table 28, characteristics solution constants).

Lime water is prepared from lime slurry in a saturator and that is used for both:

- preparing the lime solution;

- removing impurities and carbonate sludge.

static saturator

This appliance is used to produce a saturated lime solution by percolating water through a bed of lime, allowing sufficient contact time for this water to become saturated.

The lime slurry is prepared in intermittent mode. It is gravity injected or pumped into the lower part of the saturator after the level has first been lowered in the saturator and carbonate sludge and impurities drained out. Lime slurry is generally reloaded every 24 hours.

After a sedimentation period, the water to be saturated penetrates slowly into the bottom of the saturator and the saturated water is drawn off from the surface.

The saturator can deliver, as saturated lime water, 1.3 to 1.6 kg of Ca(OH)2 per hour and per square metre of area.

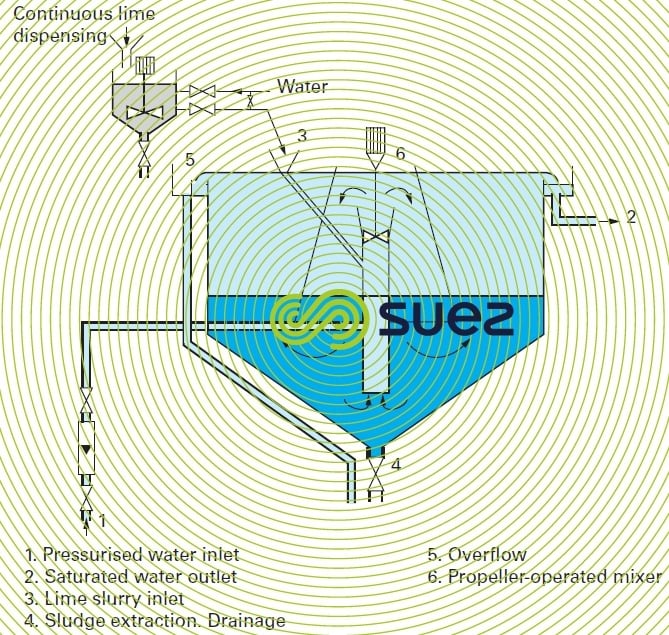

turbine saturator

For the same surface area, this appliance (figure 12) can be used to produce a higher output of lime water than the static saturator, i.e. 3.2 to 4 kg of Ca(OH)2 per hour and per square metre of area.

The lime slurry is prepared continuously or intermittently but distribution must be continuous. It is gravity injected or pumped into the sludge recycling nozzle or into the dissolution water delivery pipe.

A propeller-operated mixer (7) is used for recycling purposes; this mixer is placed in the top section of the nozzle into which the water to be saturated is also fed (1) and where the water + lime slurry + carbonate sludge are thoroughly mixed together. The saturator works with a sludge blanket whose level is controlled by the threshold in the concentrator into which this sludge is discharged.

This sludge is normally extracted through the concentrator pipes (5) and, under exceptional circumstances, by draining (4) (heavy sludge). It should be noted that all our sludge bed (Pulsator) and, especially, sludge recirculator units can be used for this purpose:

- Turbine saturator shown in photo 7;

- Circulator;

- Turbocirculator;

- Densadeg is an interesting option for high lime water flow rates.

It should be noted that adding very small amounts of ferric chloride increases the CaO content of lime water even more.

Lime saturators can also be used as lime dissolvers below the saturation level.

Figure 13 illustrates the general layout of a complete lime water and slurry preparation unit (mixing tank and saturator) often found in small to medium size drinking water installations (lime in sacks and debagger or big-bag).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later