strainer, Straining

Reading time:utilisation conditions

In addition to mechanical screens that have finer, 3 or 6 mm slots and which are necessary in some urban effluent treatment plants, it can be useful to include strainers that have narrower openings, for instance in small UWW treatment plants, making these plants easier to operate, as well as in many agrifood wastewater processing plants where straining can also take place in conjunction with the removal of a significant proportion of suspended pollution and, if applicable, recycling.

The equipment used consists of strainers in the form of perforated sheet metal or, more frequently, elements of Johnson type screens. Bar spacing will vary from 0.15 to 2 mm. We have:

- rotating drums having a capacity of up to 1,500 m3·h–1 ,

- concave assisted self-cleaning vertical bar screens (figure 3) whose capacity is limited to 100‑200 m3 · h–1.

The raw water is distributed in the form of a vertical curtain of water and the particles held back are hydraulically drawn to a lower recipient.

different types of strainer

for wastewater

In the 0.15 to 2.5 mm range, we have two main types of strainer.

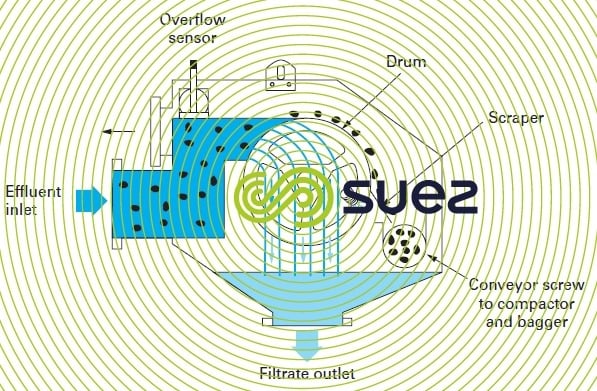

drum and rotating strainers

The loaded water is fed into the drum through the inside or the outside of the drum.

Water crosses through the strainer while the solids are held back, carried away by the cylinder’s rotation and then removed.

Depending on whether the drum is fed from the inside or the outside, the solids are removed either by scraping, or by gravity because of the slope.

In this type of system, the Prepazur (figure 2) is a drum appliance (0.6 to 1.5 mm) designed for effluent pre-treatment in small to medium size wastewater treatment plants. This system plays three roles: liquid/solid separation, compacting (screw compacter) and waste bagging (film bagger). Additionally, the problem of odours is reduced by fitting a cover appropriate to compact assemblies.

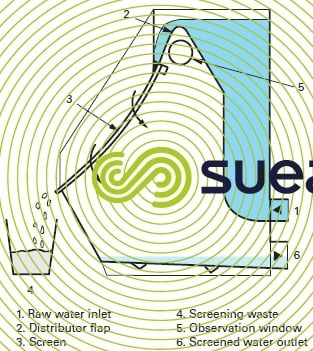

curved strainer (concave screen) (figure 3)

The strainer is a concave screen with three characteristic separate slopes; these are used to remove the greater part of the liquid (washing part) and then slow down and drain the waste.

There is a «vibrating» version of this type of strainer. These strainers are more appropriate to greasy and sticky products and to heavily laden liquids.

for surface water

macrostraining

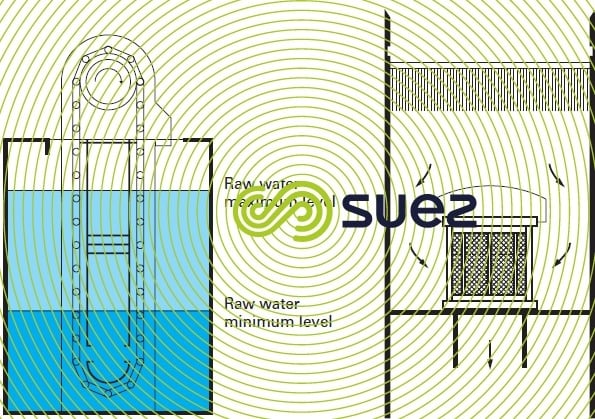

The filter elements are made up of perforated metal sheets or, more frequently, cross-mesh stainless steel or synthetic material fabrics, having 0.15 to 2 mm openings.

Strainers come as 1.5 to 6 m diameter drums or 1 to 3 m wide belts and are 3 to 15 m high tailored to suit the requirements of variable level rivers (figure 4).

microstraining

Filter belts made of synthetic material have a 30-40 mm to 150 mm mesh. These belts are mounted on drums. Washing equipment must be able to provide a much more intense spray capable of «passing through» the belt in order to dislodge fine sand and silt caught up in the mesh.

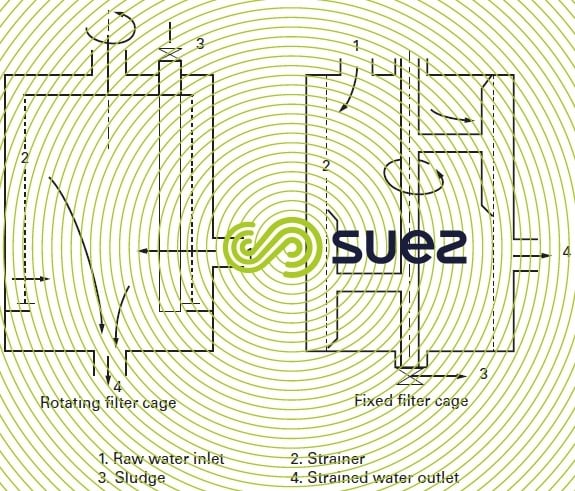

In industrial water applications, in order to protect delicate appliances or circuits (e.g. sprayers, UF or MF systems, filter belt wash systems …) pressurised microstraining or macrostraining systems, also known as mechanical filtration, can also be recommended.

These filters (figure 5) have a semi-continuous wash system that removes sludge simply using the ambient pressure, by counter current over a section of the filter. Wash pressure has to be adapted to the filtering belt’s mechanical strength.

In order to avoid irreversible fouling and an excessively high wash water consumption, in practice, the fineness of the pressurised system’s strainer mesh often has to be limited:

- to 100-150 μm, for water laden with organic matter and plant debris

- to 40-50 μm, when water only contains granular mineral matter.

Fibres are especially prejudicial because they tend to attach themselves to the belts. There are two possible types of construction (figure 5). Output per unit of equipment drops as the straining fineness increases. Above 250 μm, output can reach 5,000 m3·h–1 and in microstraining up to 500 m3·h–1. Wash water losses vary, for the same conditions, from 2 to 8%.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later