grit removal general

Reading time:object

The purpose of grit removal consists in extracting gravel, grit and more or less fine mineral particles as well as fibres from raw water in order to prevent the formation of deposits in channels and pipelines and to protect pumps and other appliances against abrasion.

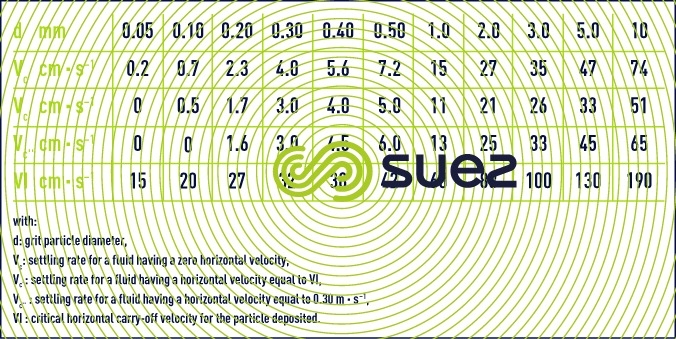

The data featured in table 3 (applicable to free settling in the case of grit particles having a 2.65 density) can be used to establish the removal capacity of a grit remover of a given geometry. In fact, grit remover design is subject to two problems:

- grit mainly arrives when there is a throughput peak (sewer self-cleaning) during which the cross velocity is at its highest and, consequently, the suspension reinstatement rate also at its highest;

- in wastewater treatment, the aim is to extract the most mineral matter (Mm) containing the least organic matter (generating nuisances during storage and removal) from the water.

In order to separate organic matter from mineral matter, we need to maintain an adequate turbulence, whence the inclusion of cross mixing, normally using compressed air.

utilisation conditions

The normal domain of grit removal concerns particles having a granulometry equal to or greater than 200 µm, or even 300 µm; lower granulometry values are usually come under the auspices of sludge removal or settling (see Flocculators – settling tanks – flotation units).

The theoretical analysis of grit removal is linked to that of discrete particle settling (see different types of sedimentation).

quantity of grit – characterisation

The quantity of grit present in effluent is extremely variable and depends on:

- the region’s prevailing geological features;

- pipeline condition and length;

- network type: separate, combined, mixed systems, network maintenance;

- rainfall episode frequency.

In general, no more than 15 litres of grit per year and per inhabitant will need to be extracted.

We need to emphasise the problems encountered when determining the quantity of grit arriving at a plant or the efficiency (or removal capacity) of a grit remover:

- sampling constitutes the main problem. In effect, a very high level of turbulence is required in order to maintain grit measuring over 0.3 or 0.4 mm in suspension, whereas it is easier to take samples at the outlet;

- additionally, «grit» refers to all discrete particles held back by a series of screens from the burnt suspended matter found in the sample; these particles also include sand as well as a range of mineral waste which is often more or less porous such as small fragments of glass, concrete, pottery, earthenware … Therefore, if we want to establish grit removal efficiency, we have to specify that this only refers to matter that has a density greater than 2.5 for instance, and, consequently, apply a classification to settling in a dense medium.

Comment: in table 3 used as the basis for designing grit removers, the density applied is 2.65.

grit treatment

Grit is usually treated with a view to reducing the organic matter content; «grit» collected at the grit remover outlet is sent on to a specific treatment that includes:

- hydrocyclone;

- classifier;

- grit washer.

When an Arenis type treatment unit (see processing cleaning waste: arenis) is available, the grit is sent there for processing.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later