a high performance biological process - Biofor®

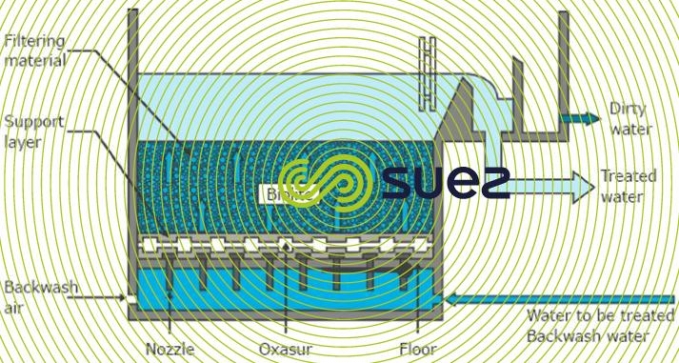

The Biofor® allows an advanced treatment of suspended solids (SS) and carbon and /or nitrogen pollution with no odor. The effluent to be treated is continuously fed into a biological reactor called a « biofilter », passing through materials that retain the suspended solids.

Carbon and/or nitrogen pollution is eliminate due to the development of natural bacteria into a fixed biofilm (purifying biomass) on a mineral support that is also natural, the BIOLITE®.

BIOFOR TYPE | APPLICATION | |

AERATED BIOFOR® | Biofor® C Biofor® CN Biofor® N | Carbon (BOD) Carbon and partial denitrification Tertiary nitrification |

NON-AERATED BIOFOR® | Biofor® Pre-DN Biofor® Post-DN | Upstream denitrification Downstream denitrification (methanol added) |

key figures

- 74,000 m2Installed surface

- 1,150 Degrémont® BIOFOR worlwide

- Density > 1. No material loss

among references

- Chengdu Petrochina (Refinery) 60,000 m3/d

- Xiamen (China) 300,000 m3/d

- Louis-Fargue (Bordeaux, France) 276,000 m3/d

- Sophia Antipolis (France) 50,000 PE

- A high-performance treatment complying with regulations for all types of effluents (low-temperature effluent, effluent with wide variation in flow and/or load, diluted effluent, industrial effluent such as oil, paper pulp, etc…)

- Limited footprint, easy to cover due to its compactness

- Easy on-site implantation (modular aspect)

- Adapted to extension and refurbishment

- Easy to operate due to automated functioning

- A natural material:BIOLITE®

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later