tubular modules

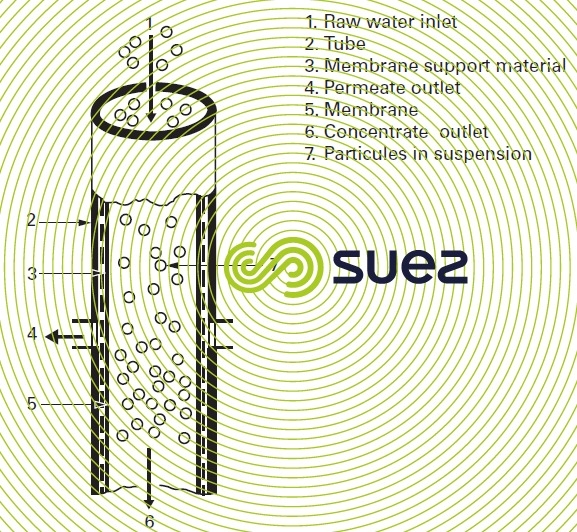

Reading time:The membranes are placed or directly formed inside a support tube (porous or pierced with drainage holes) whose diameter will vary between 4 and 25 mm. These tubes are then placed in parallel or in series in a cylindrical casing to form the modular unit (figure 1).

The discharge hydrodynamics have been totally defined and circulation velocities of up to 6 m.s-1 are feasible if very high turbulence operating conditions are necessary. These modules do not call for a fine preliminary filtration of the liquid to be treated and are easy to clean (regular use of sponges in the form of small balls). The major drawback of these modules is that they are not very compact and that they have a high cost per m² installed. They are particularly well suited to processing loaded or highly viscous fluids. These modules are also used to treat water in a few cases where, processing low throughputs, the aim is to control scaling by maintaining a crystal suspension in the concentrated liquid or to control fouling through the use of sponges.

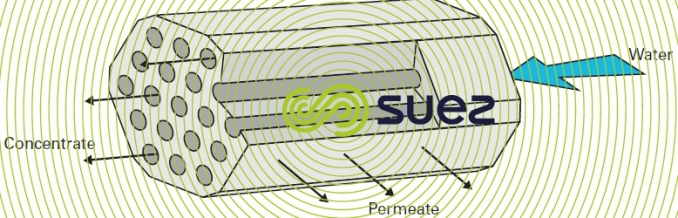

The same geometry also applies to the ceramic membrane modules that are obtained by extrusion and that have been used successfully in MBR installations for IWW treatment (in this case, we need to remember the system will be sensitive to fibres – figure 2).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later