characteristic anaerobic digestion parameters

Reading time:Depending on the mechanisms quoted above, the following parameters are the most important:

- temperature;

- pH;

- loading rate of the digester expressed in kg CODm-3.d for liquid effluents and in kg VS.m-3.d for sludge;

- actual contact time and the reactor’s hydraulics;

- the biomass concentration and method used to put the biomass in contact with the substrate are two parameters that separate the different processes – anaerobic bacterial cultures utilisation.

biogas

To monitor methanisation or anaerobic digestion, gas composition and production are the two most important parameters used in monitoring anaerobic digestion.

The composition of the gas that is formed depends on the substrate composition and on fermenter operating conditions (loading, contact time).The following figures can be used as a rough guide:

- CH4: 50 to 85 % for wastewater and 60 to 65% for sludge;

- CO2: 25 to 40 %(wastewater and sludge)

- N2:1 to 7 %

- Siloxanes : from 0 to 100 mg/Nm3 (namely present in urban waste)

There may also be other products present including H2S and mercaptan produced from mineral (usually SO42–) or organic sulphur present in raw sewage and the sludge as well as NH3 produced from biomass proteins(from 0 to several hundred mg/Nm3).These elements are responsible for the unpleasant odour that is characteristic of this gas.

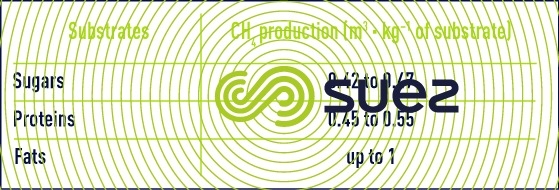

The quantity of CH4 formed will also depend on the nature of the substrate. Table 13 provides a few details.

In every case, methane production will be in the region of 0.35 Nm3 per kg of COD degraded.

In sludge digestion, biogas production varies from between 0.9 Nm3 and 1.1 Nm3 per kg of VM eliminated.

sludge production

In IWW treatment applications, an excess biomass production of between 0.05 and 0.1 kg DM · kg–1 of soluble COD eliminated will be required. This figure is low compared to the figures obtained for aerobic digestion (0.2 and 0.4 kg DM per kg of soluble COD eliminated). The recyclable CH4 output (boiler – heat engine) together with this figure constitute the overwhelming advantages offered by anaerobic processes.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later