slow filtration

Reading time:Sometimes designated by its Anglo-Saxon acronym, SSF (Slow sand filtration), it was originally applied during the first half of the 19th century (e.g. Chelsea, 1829). At a time when surface water was not heavily polluted and when standards were not so stringent, slow filtration appeared to be the ideal «ecological» treatment, imitating nature’s way of producing spring water because the water would percolate through a filtering medium without any added chemical product.

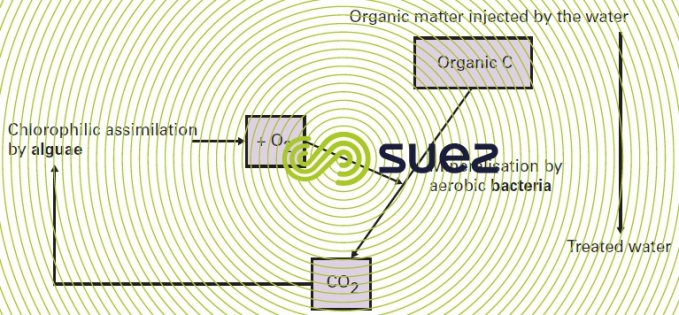

In the original design of this treatment, raw water only underwent physical pre-treatment (micro-straining, or rapid pre-filtration through gravel and/or sand in "prefilters" that might be preceded by “roughing” systems) before being delivered to "polishing" filters through which it percolated at the rate of approximately 5 m · d–1 (in other words, modern fast filters work 30 to 50 times, or even more, faster); slow filtration sometimes only uses bacteria (especially in cold countries where tanks will also be covered over); however, what often happens is that after a certain maturation period, a complex biocenosis made up of algae, bacteria and zooplankton (the latter acting merely as a predator and having a limiting effect on the two former) occurs on the surface of the sand; in this medium (termed biological membrane or schmutzdecke in Anglo-Saxon texts), a complex symbiosis occurs between algae and bacteria (similar to that found in a natural lagoon, see different types of lagooning):

Overall, the various modes of action of a slow filtration biomass can be summed up as follows:

- mechanical retention and screening effect, in two successive media: the biological membrane and the sand itself;

- bioflocculation using exopolymers secreted by algae and bacteria;

- bacterial oxidation, thanks to the dissolved O2 present in raw water and to the O2 produced by algae; nitrogen ammonia nitrification, mineralisation of biodegradable OM;

- sequestering (heavy metals), bio-accumulation (detergents, pesticides), metabolisation (phenols, pesticides);

- elimination of pathogenic bacteria through the ‘struggle for life’ system, bioflocculation, predation, antibiosis (some green algae such as Chlorella or Scenedesmus, being capable of secreting bactericidal substances).

The head loss changes very slowly as the result of low filtration rates and, on average, filters are washed once a month. Washing is usually manual (using pressurised water jets) and sometimes mechanised (descaling).After a wash has been completed, the filtered water will not always be satisfactory and it will have to be run off into the sewers until the biological membrane has reformed. This process takes several days.

Slow filtration gives good clarification results providing that the suspended solids content of raw water is low and providing that the final filtration rate remains low; however, as soon as the suspended solids content increases, roughing systems, bar screens and pre-filters become inadequate and the treated water turbidity can rise well above the limit set by the standards if the filtration rate is not reduced even further. Furthermore, these filters are sensitive to high levels of plankton algae in raw water (surface fouling). Some species have proved to create particularly high levels of fouling (e.g. the Asterionella diatom, ref. 15 in figure 6, and the green algae Pediastrum, ref. 7 in figure 7, in micro-organisms for which freshwater is their natural habitat).

Additionally, slow filters that work on a water with high content in organic matter and chemical pollutants, can still deliver a water that tastes unpleasant and that contains inadmissible residual levels of micro-pollutants (phenols, detergents, pesticides); thus there will only be a 50% organochlorine pesticide elimination efficiency. Heavy metals also will be incompletely screened out.

Furthermore, slow filtration can no longer be widely used due to the ground surface area and labour it requires. However, it may still be considered:

- for small, isolated water treatment plants in hot climates;

- for infiltration beds used to replenish the water table using pre-treated river water (e.g. SUEZ’ water treatment plant at Croissy-Le Pecq (France), see artificial aquifer recharge);

- in combination with modern treatments when slow filtration is already being used, in an old water treatment plant that is to be refurbished such as the one referred to above (see background and general features); in these cases, slow filtration becomes a mere post-clarification and/or pre-polishing stage, incorporated into a more complex system.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later