bio-S process

Reading time:The Bio-S is a treatment plant that uses low load activated sludge, with one single reactor that uses the SBRprinciple. The Bio-S has been designed and standardised for small communities with a 200 to 2 000 PE capacity. These systems are available with steel or concrete tanks.

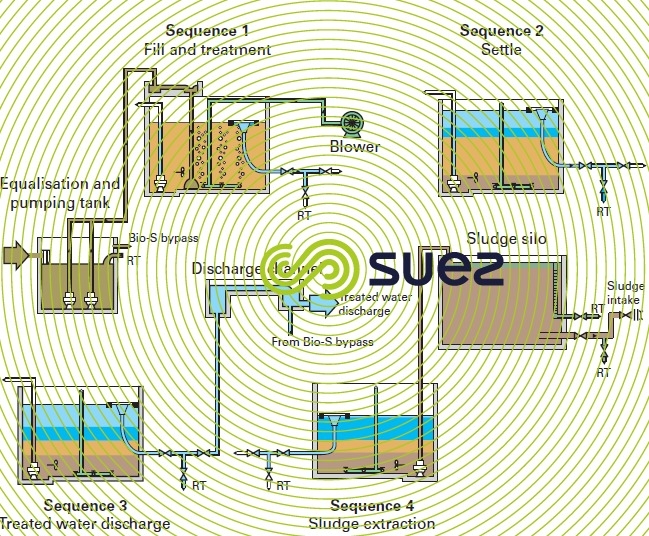

operating principle (figure 39)

The Bio-S comprises a variable level biological reactor linked to a buffer tank that is used to store the influent and to provide the biological reactor with an intermittent input.

This system has a cyclic operating mode. A typical cycle includes the conventional RBS sequence of phases:

- filling/aeration for carbon treatment and for nitrification, and/or filling without aeration for denitrification;

- sludge settling and clarification;

- treated water decanting;

- removal of excess biological sludge.

The number of daily cycles and the duration of the different phases can be programmed according to throughput fluctuations and to raw water properties. The Bio-S has been designed to run on a 24-hour cycle or on two 12-hour cycles in the case of highly concentrated water, or on two 12-hour cycles or four 6-hour cycles with more dilute water (classic urban wastewater).

description of the installation (photo 13)

A Bio-S plant comprises:

- a buffer tank that plays three roles: pumping bar-screened wastewater, adjusting hydraulic peaks, storing raw water during the clarification and drainage phases;

- a single biological reactor comprising aeration using injected air, a submerged mixer, an automated decanter and extraction of the sludge produced;

- a sludge storage silo with a vertical drainage screen;

- a system management mechanism quipped with a programmable logic controller and remote surveillance.

applications and advantages

Areas of application primarily involve typical household wastewater and agri-food industry effluent (especially dairies and cheese-makers).

The advantages of the process are those inherent to the SBR technology, with specific benefits for the applications concerned:

- simple operation;

- no submerged moving equipment (in particular, no scraper bridge);

- excellent sludge settling capability;

- comprehensive automated controls with remote surveillance;

- easily integrated into the site.

Photos 14 and 15 illustrate the compact nature of the system (1 single «block») and its ease of integration into the site.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later