biological process design software : ondeor

Reading time:A wastewater treatment plant can be designed in a global manner by applying ratios prorata to the number of population equivalents. This approach will provide a rough estimate of the tank sizes required.

However, for accurate dimensioning, allowing for the plant’s specific features and especially the quality of the water to be treated, appropriate designtools have to be used.

To this end, SUEZ has developed a series of in-house software packages (named Ondeor) used for dimensioning activated sludge plants, biofiltration and membrane bioreactors.

The modelling programmes used by this software are based on basic formulations (Monod equations, effect of temperature on kinetics …), supported by longterm monitoring results for plants that are already in operation. This is particularly applicable to primary settlement performances, nitrification and denitrification kinetics, biological phosphorus removal, sludge production and oxygen demand.

Additionally, the inputs needed are based on the raw water’s typology (see wastewater typology). Each component of each parameter used to define pollution undergoes a different processing, especially at primary settling, soluble carbon consumption for denitrification and biological phosphorus removal...

Consequently, this software is used to dimension the entire water train in terms of primary settling surface area (whether or not physical-chemical), tank capacities (aeration, anoxic, anaerobic ...), sludge production, oxygen requirements, clarification surface area and type of tertiary treatment in order to achieve discharge targets and to do so regardless of the technologies considered (activated sludge process, Biofilters, Ultrafor, Cyclor, Météor,…).

In parallel, sludge line definition and dimensioning can be used to quantify returns from the sludge treatment system. These returns, depending on their origins and on the system’s configuration, are either injected into the primary settling inlet or into the biological reactor inlet. Here again, soluble and particulate components undergo different processing: any soluble pollution is treated as additional pollution; any particulate pollution is regarded as inert and, therefore, in transit to sludge treatment. These returns usually represent approximately 2% to 15% of the pollution and of the raw water flow rate depending on the treatment processes selected.

When these returns are taken into consideration, this results in a more or less significant increase in water line and sludge line sizing.

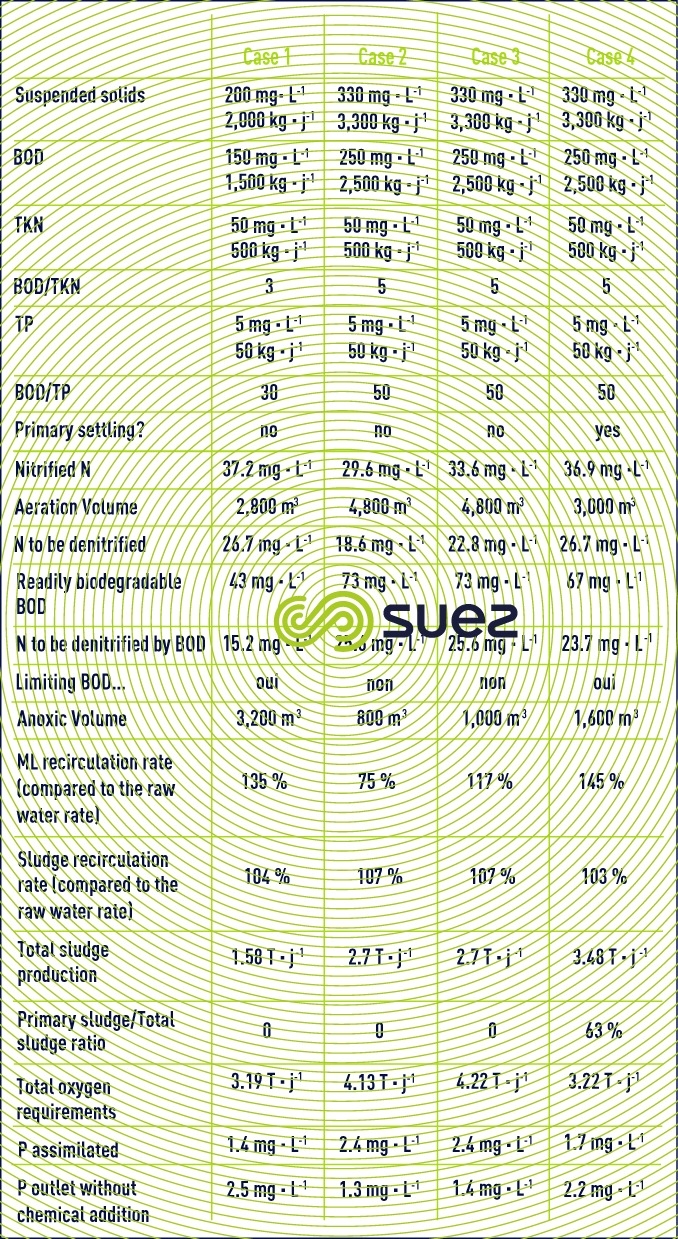

The following table provides several design examples for the same 10 000 m3·d–1 plant according to different scenario: more or less concentrated effluent, sludge returns taken into consideration, presence or absence of primary settling.

Plant definition:

Q = 10 000 m3 · d–1

Temperature = 12 °C

Discharge NT = 15 mg · L–1

Activated sludge configuration: Pre-anoxic at the head of the line - Aeration – Secondary sedimentation with or without primary settling.

As can be seen from this example, the BOD/N ratio has a major impact on denitrification dimensioning:

- in case 1, the BOD in raw water will only denitrify 2/3rds of the nitrogen. The remainder will be denitrified using endogenous kinetics that are far lower, resulting in a very large anoxic tank capacity;

- in case 2, for an identical NK concentration, having more BOD means that exogenous kinetics can be used to denitrify all the nitrogen. The anoxic volumes (case 1 minus 3,100 m3) and recirculation rates will then be significantly reduced. On the other hand, for a plant processing 1.6 times more BOD, the aeration volume will increase by 2,000 m³; similarly, phosphorous absorbed by simple assimilation is significantly higher. As can be seen, the increase in oxygen demand is not strictly proportional to the increase in BOD5 loading. In fact, the increased demand required for carbon elimination will be offset by the reduced demand for nitrogen elimination because of nitrogen’s higher natural assimilation capability and of the drop in the biomass contained in the tank;

- case 3 takes into account sludge returns from a thickening, digestion and dewatering treatment system. This approach, especially taking soluble compounds into account, results in increased capacities (especially anoxia) and recirculation rate (117% instead of 75%);

- case 4 is used to compare the impact made by primary settling on solution 3. Tank capacities are then noticeably reduced. The production of total sludge, inclusive of primary sludge, remains higher and, accordingly, sludge returns are increased.

Thus, dimensioning tools allow the designed to try out various configurations in order to optimise his design which then provides the overall cost of the plant (see treating municipal wastewater).

However, when dimensioning complex configurations or allowing for high pollution fluctuation situations, the use of simulation tools becomes an absolute necessity (see suspended growth (activated sludge) process).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later