abw filters

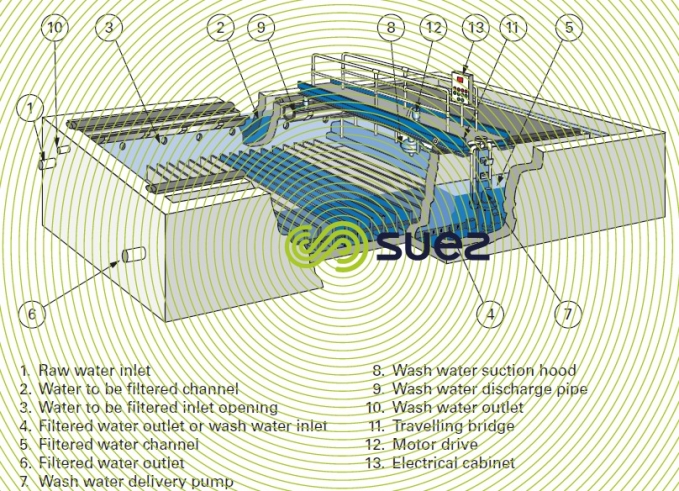

Reading time:The ABW® (Automatic BackWash) filters are sand filters where each «compartment» is washed automatically (see section Filtration) ; these filters are used in drinking or process water production and, in mainly, in the tertiary treatment of urban or industrial wastewater.

The ABW filter design relies on a very shallow floc penetration into the filtering media (fouling restricted to the initial 5 to 10 cm of the media), under normal operating conditions (fine media, short cycle), resulting in low head losses (15 to 25 cm of WC). This feature constitutes a major advantage when «refurbishing» existing plants because this type of filter can often be inserted into the plant’s hydraulic profile without the need for pumping (limiting energy costs and the danger of the floc breaking up).

In order to maintain this low head loss, the ABW filter is washed automatically and at relatively frequent intervals. The ABW filter bed is divided into compartments: an automatic mechanism washes each compartment in succession while the rest remain in service.

filtration

The filtration rate usually ranges from 5 to 7.5 m · h–1. A wash is activated when the head loss exceeds the clean bed figure by 5 to 15 cm of WC.

The filtering layer and the floor are compartmented. The filtering media normally comprises a 30 cm layer of sand laid over porous polyethylene or specially designed ceramic plates.

In drinking water applications, the sand layer can be up to 60 cm deep; alternately, a 40 to 60 cm dual-layer bed of sand/anthracite can be used or even an activated carbon layer of up to 120 cm deep.

During the filtration process, the water supplied by the feed channel enters through the openings positioned above the filter bed before crossing through the media and the floor and flowing into the filtered water channel through openings located beneath each compartment.

backwash

The backwash procedure is activated when a preset head loss is reached or after a given period of operation. Once it has been initiated, the backwash progresses from one end of the filter to the other, all the compartments remaining in service with the exception of the one being washed: the automatic backwash equipment is suspended from a travelling bridge and draws water out of the treated water channel before delivering it beneath the floor of the compartment being washed. The wash water expands the filtering layer until fluidisation is achieved, releasing particles screened out by the layer.

These particles are collected by a hood and a pump suspended from the travelling bridge and then discharged into the dirty wash water channel. The bridge moves along the filter, washing each compartment in succession until all have been washed and until head loss has reverted to a normal level. As the treated water channel contains enough water to supply the backwash pump, there is no need for a clean wash water storage tank. When the bridge has reached the end of the filter, it parks up, pumps switched off, until the head loss again reaches the set point.

The wash is not pushed to extremes. The short cleaning cycle, repeated at regular intervals (typically 30 seconds every 2 to 6 hours), maintains the filtering media in a basically clean condition and limits particle penetration to the top 5 to 7.5 cm of the filter bed. The advantage of the presence of matter in the upper part of the bed is that it improves suspended particle capture during filtration.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later