filtrazur filters

Reading time:These filters have the particular property of using a filtering media that is less dense than water and this requires special technological options, especially regarding:

- general hydraulics: the water percolates through the filtering media from the bottom to the top, the media being held in place by a nozzle floor positioned above it;

- the backwash mode: fluidisation using the back water downflow.

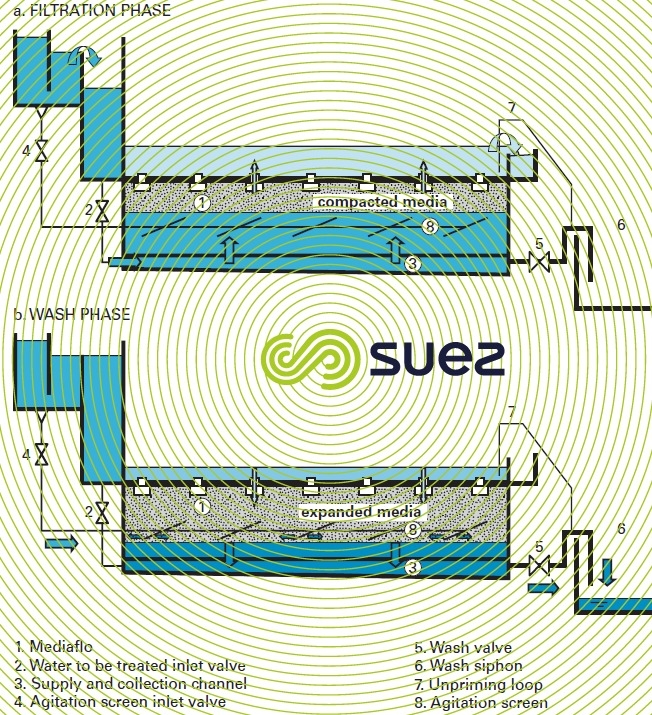

Therefore, Filtrazur filters (figure 14) have the following characteristics:

- a filtering media, Médiaflo consisting of expanded polystyrene having an apparent density of 40 to 60 kg · m–3;

- a filtering media that is 1.0 to 1.5 m deep;

- a filtering media having an effective size that is usually close to 1.1 mm (range: 0.55 to 1.7 mm) and an extremely low uniformity coefficient of approximately 1.2 to 1.3;

- inlet through a channel positioned beneath the filter floor, and filtered water collection through a nozzle floor followed by a weir;

- a backwash water tank (usually 80 cm) located above the nozzle floor and a depth of approximately 1.50 m of water beneath the filter bed used to expand the filtering media during the wash stage;

- a countercurrent backwash during which the filtering media expands, the water travelling downwards as the filter empties out rapidly at a flow rate of approximately 70 m3·h–1·m–2, depending on Médiaflo granulometry. Additional washing energy is supplied by water jets diffused through an agitation screen, at a flow rate of between 7 and 25 m3·h–1·m–2.

Filtrazur filters can be made of metal (usually circular in section) or concrete (usually rectangular in section).

These filters can be arranged in batteries, fed by the same channel, wells and weirs ensuring even distribution. Alternately, these filters can be fed by means of a pumped system, via their agitation screens and, in such cases, head loss will be calculated to ensure that an adequate evenness of distribution is maintained between the filters. In both cases, Filtrazur filters require no control unit.

Filtrazur filter washing

The wash takes place according to the following sequences (figure 14 b):

- the water to be treated inlet (2) is closed; the water to be treated goes to the agitation screen (9) as a valve (4) opens;

- the filter is partially drained as wash water valve (5) opens; the water drains out via a wash water evacuation circuit comprising a collection channel (3), an adjustable setting valve (5) and a siphon (6); the drainage output is such that the velocity of the water through the filtering media causes the media to fluidise;

- the drainage function is switched off by unpriming the siphon (air enters into the unpriming loop (7) when its aperture (8) is open to the atmosphere);

- raw water rinse via the agitation screen;

- the filter filling: the wash water evacuation circuit is closed, supply to the agitation screen is shut down and water supply via the channel is resumed.

Given the time taken by the valves to operate, the wash takes 10 to 20 minutes and ends with the filter refilling back up to its normal filtration level.

advantages of the filtrazur filter

This filter incorporates all the principles that are characteristic of good filtration and efficient washing:

- the water flows in the direction of material compression against the floor, as in a sand filter, producing a filtration quality that is identical to that obtained with a sand filter of the same granulometry;

- the water to be filtered continues to supply the entire filter throughout the wash period, via the agitation screen; therefore, during that period, the remaining filters in the same battery are not subject to sudden increases in flow rate and, consequently, in filtration rate;

- it is particularly well suited to high filtration rates (7 and 25 m3·h–1·m–2), because its filter bed is not subjected to the dangers of negative pressures arising during the filtration cycle;

- Médiaflo’s very tight granulometry (uniformity coefficient of approximately 1.25) avoids any danger of the filter bed being hydraulically regraded during a wash;

- in the absence of rotary machines (there are neither wash water pumps nor air scour blowers), this system is simple to operate and maintain and very little energy is consumed by the washes;

- this system consumes roughly the same amount of water as the Aquazur V and this consumption will usually fluctuate between 1 and 3% of the filtered volume, depending on the nature of the water to be treated.

Furthermore, the surface condition of the Médiaflo filtering media encourages the attachment of nitrifying bacteria enabling the Filtrazur to also remove ammonium within the limits of the dissolved oxygen contained in the water, unless continuous aeration is implemented.

standards dimensions

- metal construction: diameter between 0.95 and 3.5 m;

- concrete construction: surface area between 30 and 75 m2.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later