filters suitable for successive water and air washes

Reading time:These apparatus are filters with a lower return system and a large diameter flow, which is filled by several support layers of the filtering media itself. In the upper support layer, an overpressurized air diffusion network is installed.

Even if this filter does not produce a water quality comparable to that produced by a FV2B, it has the advantage of being able to be washed using raw water, even if this water contains suspended solids. It is perfectly suited to derived filtration on a cooling circuit for example.

Furthermore, in industry, and namely on cooling circuits or on water loaded with adhesive organic matter, air scouring followed by a water wash is often preferred, air scouring permitting sand grain to be better cleaned through the attrition phenomenon.

On the other hand, when cleaning consists in air scouring alone, the grain separates from the gang of OM, but it is not drawn to the top of the filter. It is therefore the next phase, which consists in a water wash, which will evacuate the OM from the filter. Wash sequences for these FVF filters are as follows :

- lower in water level at the level of the upper diffuser;

- De-clogging using water (15m/h for water at 15°C) (it consists in eliminating the suspended solids which is namely concentrated at the top of the filtering media, and loosening the bed of sand) ;

- A further fall in the water level below the upper diffuser (in order to avoid a sharp fall in water during back-scouring with air) ;

- Back-scouring with air (50 m/h) ;

- Backwashing with wash (15m/h for water at 15°C) ;

- Rinsing with raw water (maturation) at normal treatment flow.

The above filters can also be loaded with a layer of lightweight material (anthracite, pumice, activated carbon, biolite) or with two layers of different materials (dual-layer filters). They then require two successive wash phases and, before injecting air scour , the water head has to be lowered.

When the fine material in the dual-layer is sand, the return water flow rates required are those featured in the table for filters using return water only, subject to the same size of sand. These flow rates are higher than those used for homogenous single layer filters; pipes, valves and wash pumps must be dimensioned accordingly. Additionally, filter bed expansion requires the filter backwash water removal collection system to be raised up.

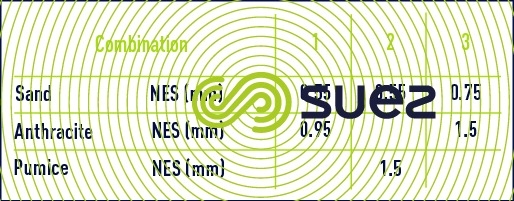

The following table (table 2) gives the characteristics of compatible filtering material combinations applicable to the most common dual-layer filters :

Comment: other combinations are possible

FH (type FH-L) filters

One or two-launder horizontal filters with a specific arrangement for collecting wash water (figure 8).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later