filter washes

Reading time:One or two fluids (usually filtered air and water, see section filtration) are always used in upflow mode to wash filters, except in special cases (filtering media that is lighter than water: Filtrazur).

washing fluid distribution

Therefore, a system used to distribute one (water) or both of these fluids must be included beneath the filtering media, air being subject to specific requirements. There are two possible ways :

- simple water backwash collectors;

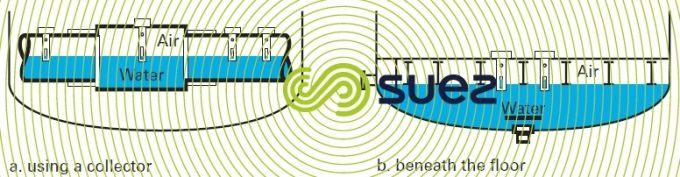

- air blanket devices set up beneath the floors or in special laterals collectors (air scour and water wash).

water backwash collectors

These systems can be made up of tubular laterals connected to a central unit or to a transversal distribution collector. The laterals have holes or nozzles that distribute the water.

air blanket devices

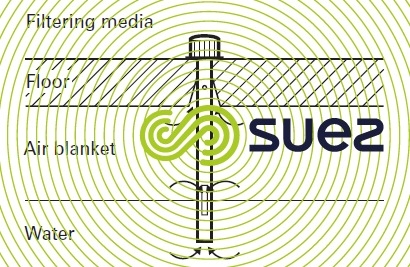

Stemmed nozzles are needed in order to maintain an air blanket and to distribute the air evenly. Figure 1 is a cross section of a long-stem nozzle, fitted into a concrete floor, during the air scour and water backwash sequence.

This nozzle has a head with fine slots that do not allow the filtering media through, and a stem formed by a tube with a hole in its upper section as well as a slot in its lower section.

The air injected beneath the floor produces a blanket which, once it has been formed, supplies the nozzle hole and slots, creating an air and water mixture that is then distributed over the entire filter surface. This is a particularly effective washing system that generates water savings.

In order to prevent the formation of mud-balls, 55 nozzles are required for each m² of floor, with a backflow air output of approximately 1 m3·h–1 per nozzle.

Thus, an air backwash is carried out on pressure filters in two ways (figure 2).

lightweight materials

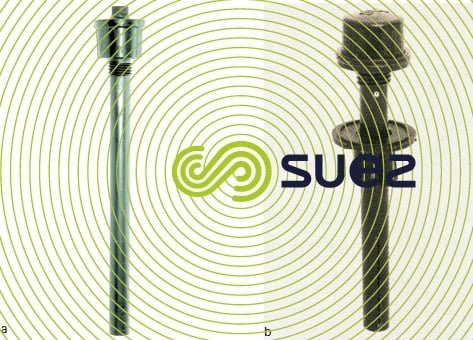

This type of media is likely to be drawn away into the drains with the backwash water when air and backwash water are present simultaneously; it is usually washed using air and then water (see section filtration through a granular bed). Special provisions are required to avoid the presence of air at the start of the rinse phase: a system of blowdown pipes collects the residual air blanket before the rinsing phase and extracts the air blanket from the filter. The upper hole in the nozzle will then be located below the floor and below the blowdown openings.

for dense materials

Dense media are washed simultaneously by «air and water», air present at the start of the rinse phase does not constitute any danger because the filter is equipped with so-called self-bleeding nozzles (figure 1): after it has been air-washed, the air blanket is removed through the upper hole in the nozzle stem and evacuation is completed during the water rinse phase. The upper hole in the nozzle will then be located above the underside of the floor. Filters backwashed using «air and water simultaneously» do not have an air blowdown system.

SUEZ’s experience has enabled the Company to develop different types of nozzles (photo 2) that have been optimised to match filtration techniques, using materials that will withstand more or less aggressive environments.

Water consumption is very closely related to suspended solids content, nature and water temperature. However, comparative orders of values can be quoted in respect of clarified water filtration :

- 1 to 3% for single layer filter (Aquazur)«air and water» washes;

- 2 to 4% for twin layer filter (Médiazur)«air followed by water» washes.

- 4 to 8 “fall in water level, air followed by water” co-volumes (SeaClean), frequently with brine washes.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later