aquazur sand filters

Reading time:Aquazur filters are backwashed using the simultaneous «air and water» method: this involves a high air flow rate return and reduced water flow rate followed by a rinse at an average flow rate that does not cause the filter bed to expand since the sole purpose of this phase is to convey the matter removed from the bed to the wash water troughs.

The main filters used are the Aquazur V at velocities of between 7 and 20 m · h–1 and up to 30 m · h–1 in specific designs; Aquazur T filters are used occasionally, especially in the event of a very tight hydraulic gradient.

Aquazur V filter

A high filtration rate of between 7 and 20 m · h–1, requires specific choices of technology, relating especially to:

- the choice and depth of filtering material;

- the backwash mode;

- hydraulics in design.

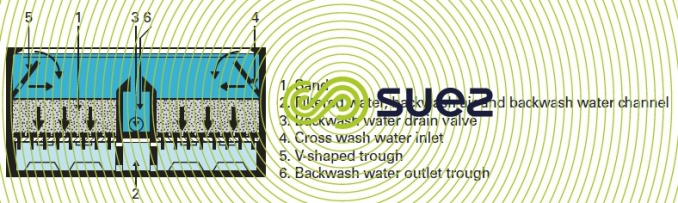

Aquazur V filters (figure 9) have the following characteristics:

- a high water height over the filter bed, equal to at least 1 m and, in most cases, 1.20 m.

- a homogenous filtering media depth of between 0.8 and 1.5 m;

- a filtering media effective size, usually 0.95 mm or 1.35 mm (extreme range: 0.7 mm and 2 mm);

- simultaneous air scour and water backwash, accompanied by a surface cross wash using raw water, followed by a water rinse which does not expand the filter bed and also accompanied by a surface cross wash. This cross wash is used to more rapidly discharge impurities to the drains, thus reducing the wash duration and, therefore, the filtered water demand for wash.

Aquazur V water level is controlled either by a partialised siphon or by a butterfly valve actuated by a Régulazur filter rate controller (see section filter control and regulation).

Aquazur V filters can be laid out as single filters (with one filter rate controller per filter) or as twin filters (two cells intercommunicating through the top and through the bottom and one single filter rate controller).

Aquazur V filter washing

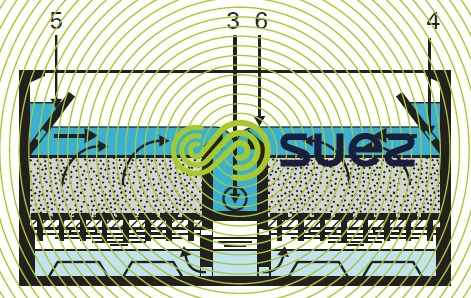

The wash follows the sequence given below (figure 10):

- the water level is lowered down to the upper edges of the wash water channel (6) by shutting off the supply;

- the air blanket is formed;

- scouring is carried out by injecting air and water with a crosswash current;

- water rinse, maintaining the crosswash current, until clear water is discharged into the drains.

The following flow rates apply:

- filtered backwash water flow rate; 7 to 15 m3·h–1·m–2;

- air scour flow rate: 50 to 60 m3·h–1·m–2;

- crosswash flow rate: approximately 5 m3·h–1·m–2

- rinsing water flow rate: 15 m3·h–1·m–2.

Given the time taken for the valves to operate, the wash takes from 10 to 12 minutes and ends when the filter is filled back up to its normal filtration level.

advantages of the Aquazur V filter

This filter combines all the principles that are characteristic of satisfactory filtration and an effective wash:

- it is particularly well suited to high filtration rates where 1 to 2 m sand depths can be used;

- it retains a positive pressure throughout the depth of the sand and throughout the entire filtration cycle;

- its wash mode, which does not expand the filter bed, avoids any hydraulic grading of the materials constituting the filter bed which, accordingly, remains homogenous, even when it comprises materials with a high uniformity coefficient (e.g. CE ~ 1.7);

- in wash mode, the filtered water return flow is low, thus reducing equipment as well as energy consumption;

- the hydraulic design is optimised, such as in the case of the wash water weirs whose profile has been designed to prevent filter materials from being drawn off;

- the filter bed’s wash using returned water throughout the air scour period is linked to the surface crosswash action. Wash water consumption tends to vary from 1 to 3% of the volume filtered, depending on the quality of the water to be treated and on temperature:

- the water to be filtered continues to supply the filter entirely or partially throughout the wash period, for surface crosswashing; therefore, during this period, the other filters in the same battery are not subjected to a sudden increase in flow rate and, consequently, to filtration rate surges;

- filtration is resumed because the level rises, leading to a gradual restart after a wash, whatever of the type of control unit selected. If required, this gradual start-up can be extended to 15 minutes.

standard dimensions

The Aquazur V single cell filters have a standardised surface area ranging from 24.5 to 105 m². Double cell filter surface areas range from 49 to 210 m².

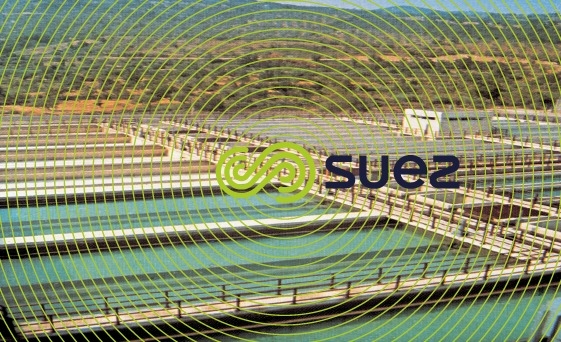

Photo 3 shows an Aquazur V filter in the process of construction; we can see:

- the filter floor with its nozzles;

- the V-shaped crosswash channel;

- the backwash water outlet trough.

high speed Aquazur filters

Aquazur V filters can be used at velocities in excess of 20 m · h–1; however, in such cases, the design has to be adapted; the Aquazur V filters at the Prospect factory in Sydney (Australia) illustrate this type of applicatione.

Prospect – Sydney Water Corporation:

- Water type: reservoir water

- Output (treated water): 125 000 m3·h–1

- Application: direct filtration

- Filter battery: 24 Aquazur V double filters

- Surface area per unit: 238 m2

- Total filtration surface area: 5 710 m2

- Filtering media: 1.8 (TE) mm sand.

The main wash and filtration parameters had been established when preliminary pilot tests were carried out (see also filtration through a granular bed):

- conditioning using ferric chloride, organic coagulant (cationic polymer) and flocculation additive (anionic polymer);

- filtering media: 2.15 m of sand (TE: 1.8 mm);

- maximum filtration rate: 24 m3·h–1·m–2;

- wash conditions:

- simultaneous water backwash + air scour; air flow volume: 70 m3·h–1·m–2; water flow volume: 30 m3·h–1·m–2;

- rinsing water flow rate: 60 m3·h–1·m–2 (with cross wash at a rate of 7 m3·h–1·m–2).

In order to ensure that there is an adequate pressure through the filter bed, given the velocity applied, the water depth above the sand was increased to 2 m.

Washing and rinsing velocities were significantly higher than the usual velocities due to the reagents injected upstream from filtration. In order to restrict washing equipment size, the cells are washed and rinsed successively, unlike the standard Aquazur V where both cells are washed simultaneously.

Aquazur T filter

This type of filter has been abandoned and replaced by the Aquazur V filter.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later