ventilation

Reading time:aims

Ventilation used in a water treatment plant may have one or more of the following purposes:

- provide fresh, healthy air to staff working in premises by renewing it;

- evacuate the emitted pollutants to ensure that the personnel operate in an atmosphere that is not hazardous to health and to protect equipment and structures;

- Manage the air flow intakes and outlets, thereby preventing diffusion of atmospheric pollutants to the outside (environmental protection).

- adjust the interior atmosphere by:

- dehumidifying the air in the premises to avoid any risk of condensation, the attendant corrosion problems and resulting fungus development;

- heating or cooling the rooms;

- evacuating the heat generated by rotating machines such as air blowers, diesel generators, electric motors, etc;

- extracting the smoke to ensure security in the event of a fire, especially by partitioning off premises at risky rooms.

the different types of ventilation

A structure or premise can be ventilated in three ways:

- natural ventilation without using an air supply or extraction fan by simply moving air through openings based on natural phenomena (natural convection, wind, chimney effect, etc.);

- single-flow ventilation with:

- either mechanical air supply and natural air outlet;

- or mechanical extraction and natural air intake;

- double-flow ventilation with mechanical air extraction and supply.

Distinction is made between two complementary ventilation strategies:

- local ventilation, combined with the containment of areas requiring ventilation. The goal is to limit the diffusion of pollutants or heat in the ambient air;

- general ventilation that ensures the quality of the air and atmosphere in a room by dilution.

containment and local ventilation

The purpose of this system is to ensure that the pollutants or heat losses cannot escape into the atmosphere. This usually involves structures that cannot be inspected save for exceptional work.

Local ventilation involves suctioning as close as possible to the emission source (pollution or heat); it applies to areas that must be accessible during operation.

natural ventilation

Confinement can signify providing the structure with a sealed cover with no mechanical ventilation (natural ventilation). This is designated simple containment. A venting system, with or without protection, must be included so that the structure can breathe and manage water levels fluctuate.

single-flow ventilation

Mechanical ventilation may also be included to enhance containment efficiency by creating a vacuum compared with the external atmosphere. The term used is vacuum containment. Where gas is produced or injected, the vacuum will only be maintained if the extraction flow rate is faster than the flow rate of the gas injected or produced in the structure.

The make-up air is usually injected into the confined area through air intake grilles (single-flow ventilation) or sometimes the leakages are sufficient. Dead spots inside the hoods are frequent, therefore. At individual points, pollution concentration can be two to five times higher than the average concentration (extracted air). This can increase the risk of corrosion.

Note: when the confined structures are inside a building, their ventilation is part of the overall building ventilation by transferring air.

Using single-flow ventilation with air blowing is not suitable for confined or local ventilation as the positive pressure in the structure is contrary to its containment.

double-flow ventilation

In certain special, sensitive cases, double-flow ventilation (mechanical air supply and extraction) may be used to manage the homogeneity of the expansion space in the confined structure and control precisely the creation of the vacuum.

general ventilation

The purpose of general ventilation is to ensure the quality of the air inside a room by dilution.

natural ventilation

Openings are made through the walls in order to renew the air in the rooms. To boost the chimney effect, air intake grilles are positioned at the bottom and air extraction grilles at the top of the building.

Although simple and inexpensive, this method still has a number of drawbacks:

- the external environment cannot be safeguarded against noise and pollution;

- flow control is problematic (in particular, it depends on the wind direction);

- problems providing appropriate heating under these conditions.

This type of ventilation is suitable for small rooms without specific pollution (transformer cell ventilation, for example).

mechanical ventilation

- single-flow ventilation with mechanical air extraction and supply.

The air is extracted from the premise mechanically, normally through a ductwork, to distribute the air extraction over the surface area of the room. The make-up air enters the premise either through openings designed for this purpose that are usually fitted with grilles, or in the form of “leaks” that are often not deliberate. The premise is in a vacuum which ensures its containment.

If S is the total section of the openings (including leaks) and Q extracted flow rate, it is agreed that there will be no backflow of air from inside the rooms towards the outside when

V = Q·S–1 is > 2 m·s–1and in the event of moderate outside disturbance (slight breeze).

A 0.7 mm negative of WC is usually enough to ensure that pollutants are not diffused to the outside of the rooms.

This type of ventilation does not transfer energy to the premise. The atmosphere in the premise is therefore not homogenised by stirring. This can often result in the presence of “dead areas” where pollution concentration can be significantly higher or lower than the mean value calculated.

- single-flow ventilation with mechanical air supply.

The fresh air is supplied to the premise mechanically through a ductwork or wall fans. The air leaves through the premise's grilles and leaks. The local has a positive pressure.

This type of ventilation cannot collect foul air flows and is therefore unsuitable for premises with specific pollution.

Given the range of the air supply jet, this type of ventilation mixes the air better in the premise than ventilation via mechanical air extraction. The blowing ductwork and inlets must be designed correctly to prevent causing discomfort. To achieve this, a maximum speed of 0.5 m/s at human body level is set.

The comfort inside the room can be adjusted (temperature, humidity) by conditioning the air supplied with an HVAC (heat ventilation air conditionning).

This type of ventilation is therefore suitable for ventilating pollution-free rooms, mainly by protecting them from pollution from adjacent premises, to evacuate the heat or to ensure a comfortable atmosphere for the staff.

- e-flow ventilation: combined mechanical blowing and extraction-flow ventilation: combined mechanical blowing and suction-flow ventilation: combined mechanical blowing and suction

This type of ventilation combines the advantages of:

- mechanical air supply (mixing the air, conditioning the air);

- mechanical extraction (collecting pollutants, containment of structures and rooms).

Blowing covers a large area and transfers its kinetic energy to the premises, thus ensuring that the ambient air is homogenous. Additionally, when fresh air is blown into the circulation areas, it produces a greater of degree of comfort for personnel.

It is even advisable to limit and control leaks as much as possible (better airtightness of buildings).

dimensioning ventilation flow rates

Ventilation must be dimensioned with the following objectives:

- evacuation of pollutants, to ensure operator safety against chemical risk and limit corrosion in the structures;

- evacuation of heat losses, mainly to ensure operator comfort but also to avoid exposing equipment to temperatures that are too high;

- evacuation of humidity, to ensure operator comfort and limit condensation, a source of corrosion;

- heating of premises, for the freeze protection.

evacuation of pollutants

It is important to ensure sufficient ventilation during emission of gaseous pollutants (rooms, confined structures) to maintain maximum permitted pollutant concentrations in the air.

Be it for premises (general ventilation) or confined structures (local ventilation), the ventilation flow rate is calculated on the basis of emission flows of pollutants and permitted concentrations in the air. These are:

- occupational exposure limit (OEL) values for rooms and buildings;

- limit values that depend on materials in contact with the gaseous pollutants for the confined structures and equipment.

Occupational exposure limit (OEL) values are regulatory values and are set out in the section about regulations.

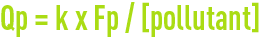

The air flow to be extracted (m3/h) is calculated as per:

With:

- Fp: Pollutant flow (mg/h);

- [pollutant]: Admissible pollutant concentration in the air (mg/m3);

- k: homogenisation factor dependent on the type of ventilation.

For surface sources, the mass flow of pollutant depends on:

- the pollutant emission surface;

- the nature of the treatment process used;

- the characteristics of the effluent treated;

- the nature of the source.

In certain situations, provided there is adequate protection of materials and thorough containment, the expansion space of confined structures can be overloaded with pollutants (gas/liquid balance), thus limiting air extraction.

evacuation of heat losses

When equipment giving off heat is installed in buildings, the heat must be evacuated to maintain acceptable temperatures inside the building (normally about 45°C).

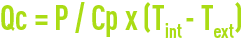

The air flow to be extracted is calculated, in first approximation, as per:

With:

- P: Dissipated thermal power (W);

- Cp: Heating capacity of the air (W.h/m3.K);

- Tint, Text: maximum inside and outside temperatures (°K).

The dissipated thermal power depends on the equipment and its output (supplier data).

condensation

Ambient air always contains water vapour. At saturation (dewpoint), the water vapour condenses.

Condensation appears on a wall where the temperature is lower than the temperature of the ambient air dewpoint (cold wall).

There is a very high risk of condensation in treatment plants due to the numerous tanks sending humidity into the air and water pipes.

Possible solutions to limit this phenomenon when there is a risk of corrosion include:

- insulating walls and ducts;

- heating the rooms;

- ventilating with outside air to adjust the amount of humidity in the inside air;

- dehumidifying the ambient air.

Thermal assessments of the risks of condensation in a room must be conducted to estimate:

- the temperatures of the ambient air and the walls (pipes, walls, roofs);

- the quantities of evaporated water at the ambient temperature of the room where there is an uncovered tank;

- the temperature of the ambient air dewpoint in the room.

Where the temperature of a wall is lower than the ambient air dewpoint, then there is condensation on this wall.

heating

The building must be heated in winter to maintain a minimum temperature of at least 5°C (frost free to protect equipment).

A room can be heated by installing air heaters or, when a fresh air system is installed in a room, by adjusting the temperature of the supplied air using an Air Handling Unit (AHU).

Traditional thermal assessments relating to the building must be applied to evaluate the required heating powers. There may be specific coefficients and calculations in different countries.

Note: ventilation used to purify the air in premises creates high air flow rates to be heated.

optimisation

Possible ventilation optimisation includes:

- minimising extraction rates by proper use of air transfer;

- recovering heat or cold, and energy, from the extracted air.

French regulations prohibit the transfer of air from premises with specific pollution to other premises. Air transfer is mainly from ambient air into a confined structure. It is also possible to transfer air from one confined structure to another.

In the case of rooms with non-specific pollution, a transfer may be used to minimise energy consumption. Thus, the air transferred from one room to another is already heated or cooled.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later