thermal de-aerators

Reading time:Steam stripping is often used to remove oxygen and dissolved carbon dioxide present in a steam generator’s feed water.

This process is implemented in thermal de-aerators where conditions in the saturating steam’s pressure and temperature are maintained so that the dissolved gases pass into the steam phase and are continually removed, with a portion of this to the outside.

Thermal degassing is carried out according to the laws described below :

Henry’s Law : The level of concentration of a gas dissolved in a liquid is proportional to its partial atmospheric pressure above the liquid; i.e. deoxygenation is made easier if the atmosphere above the liquid is low in oxygen.

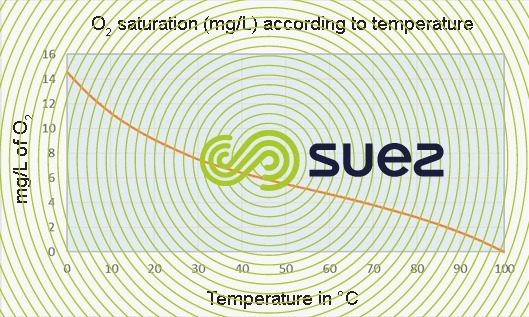

Winkler’s Law :The solubility of gas is inversely proportional to temperature.Below is a graph showing oxygen content in natural water, according to water temperature, for an atmosphere of 1,000mb.

Depending upon their design, Degrémont® thermal de-aerators can be grouped into:

- Integrated storage thermal de-aerators: degassing tank;

- Separated storage thermal de-aerators: degassing unit with packing.

These units must be equipped with safety devices :

- An air inlet valve, designed to avoid the creation of a vacuum following sudden condensation of steam;

- Protective measures against excessive pressure: hydraulic siphon or valve(s), according to the degassing pressure;

- Protective measure against obstruction: siphon or overflow.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later