general

Reading time:Distillation is the oldest technology used to obtain salt-free water from seawater or from brackish water. The principle is the same as the one occurring in the natural cycle: the heat that reigns over the oceans evaporates water as a vapor, creating clouds. When these clouds reach the coldest layers of the atmosphere, they condense and fall back to earth as salt-free raindrops.

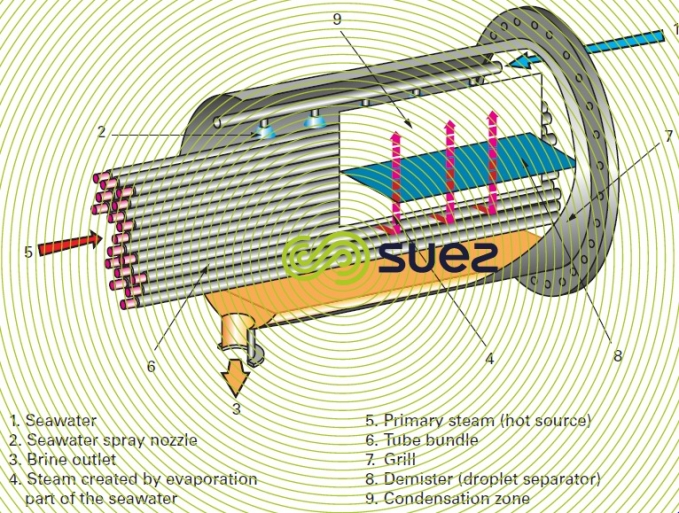

This cycle has been reproduced in industrial appliances: a hot source for evaporation and a cold source for condensation and, regardless of raw water salinity, an extremely good quality water is produced, final salinity usually being less than 10 mg·L–1 (some technologies used to separate out the brine droplets carried in the vapor (demisters) will even make levels of less than 1 mg·L–1 feasible).

The necessary energy can be supplied by a hot water or steam loop or by an electrical source. The steam is then condensed inside tubes that are cooled by seawater in order to produce desalinated water (except in the case of mechanical compression described under mechanical steam compression).

Although many types of evaporator have been offered for seawater desalination (vertical tube, plate, rising film, falling film types), the main technology used remains the horizontal tube evaporator sprayed with seawater (figure 8) where the seawater is evaporated off the tube surface (tubes heated from the inside) and the resulting steam routed to a condenser.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later