the dry solids contend approach of an industrial centrifuge

Reading time:This laboratory procedure applies to all sludge. It is used to predict the dry solids content that can be achieved with an industrial clarifier.

test principle

Sludge is first flocculated using an appropriate polyelectrolyte, i.e. a polymer that produces a resistant and large floc, which releases a maximum of interstitial liquid for a minimum amounts of polymer. The selection of the flocculent should be made according to the procedure detailed in drainability tests taking care to select the floc that is best at withstanding vigorous agitation.

Flocculated sludge is then drained through the sample screens.

The sludge drained and subsequently thickened is placed in the filter scoops of a laboratory centrifuge. The sludge is centrifuged at 2,000 g for 5-10-15 and 20 minutes.

apparatus

- GDD screen, GDE6 screen or GDE8 screen (for drainage);

- laboratory centrifuge:

- 2,000 g centrifugal field;

- fitted with a spindle (four-point star) to hold the centrate collection scoops and the metal filter scoops.

- solid scoops: optimum capacity = 200 to 250 mL.

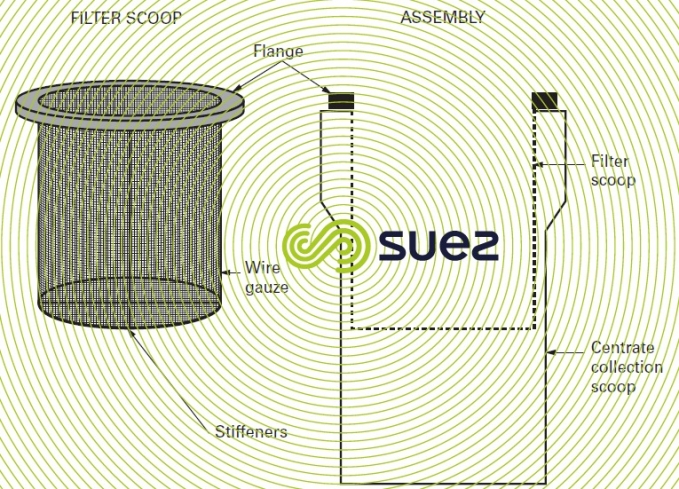

- filter scoops: optimum capacity = 100 mL (photo 8 and figure 23):

- four 100 µm mesh scoops: for “fine” sludge, without support and with a high proportion of biological sludge and hydroxides;

- four 200 µm mesh scoops: for more heterogeneous dense or fibrous sludge such as sludge containing a high proportion of primary sludge.

operating method

sample to be processed

- minimum of 10 litres of sludge;

- establish sludge properties:

- suspended solids (g· L-1)

- dry solids content (%)

- pH

- loss to heat (105-550 °C) = DS-VM;

- choice of polymer (on samples of at least 500 mL): refer to Büchner drainability tests (see drainability tests);

- test carried out with a classic solid scoop filled with sludge that has been flocculated at 2,000 g for 5 minutes.

filter scoop test (100 or 200 mm)

Once the mesh has been selected proceed as follows:

- drain the 500 mL of flocculated sludge as specified for the drainability tests using screens (see drainability tests);

- fill each of the four filter scoops up to the flange.

Note: the amounts of polymer used for test purposes produce a 20% excess amount compared with the normal beaker amount.

Centrifuge for 5-10-15 and 20 minutes.

Note:interrupt centrifugation every 5 minutes to mash up the cakes in the scoops using a metal spatula in order to break down any water pockets that may have formed

interpretation of results

Our experience has shown that an industrial centrifuge used at its nominal operating rate and with an optimum amount of reagent produces a cake having a dry solids content close to that obtained with measurements carried out on filter scoop pellets (depending on sludge type, we use the 10 minutes or 20 minutes test to forecast the industrial scale dry solids content).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later