sludge removal mechanisms

Reading time:internal collection

The above descriptions of the different clarifiers specified whether or not they included a scraper mechanism:

- without scraper system: the sludge is gravity concentrated in single or multiple hoppers. The slope of the walls of these hoppers must be greater than the sludge's natural angle of repose (40 to 70°);

- with scraper system: bottom sludge is propelled by a scraper mechanism towards one or more collection pits designed to avoid the formation of deposits. In some cases, such as the very wide rectangular clarifiers, the pit itself needs to be equipped with a scraper or a screw because, on economical grounds, it is impossible to construct it with a slope that is sufficiently steep to allow the sludge to flow naturally.

Suction systems alone can be used to collect low concentration sludge without using hoppers.

collection

This can be accomplished by gravity providing the load is adequate and that the nature of the sludge (viscosity, thixotropy, texture…) allows. In other cases, the sludge must be immediately pumped out.

Sludge is extracted intermittently except in a few special cases:

- external recirculation;

- major blockage risks.

general provisions

Sludge extraction lines must be designed so that any danger of blockages is avoided. The following rules must be adjusted to suit different types of product:

- ensure that there is an adequate velocity, at least from time to time, to prevent the formation of deposits;

- never install pipelines of too small a diameter;

- lay pipelines in straight lines whenever possible;

- reduce pipe suction lengths;

- only use perforated pipe collection over short lengths and for very fluid sludge;

- provide pipeline drainage and flushing systems (water and/or compressed air) or even mechanical raking (steel works).

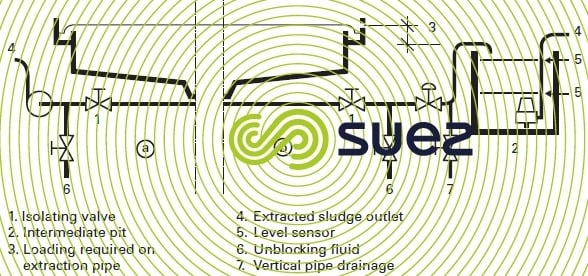

Figure 25 gives two examples of constructions used with sludge from concentrated industrial wastewater for:

- direct collection;

- with intermediate storage pit. The latter system allows the operator to carry out visual checks as well as different instantaneous flow rates between clarifier extraction and sludge removal.

Please refer to sludge handling and storage for recommendations on sludge handling, including liquid sludge.

automation

As sludge extraction is almost always intermittent, automating this function can be an advantage. Depending on the applications, interlocks can be achieved in a variety of different ways:

- by means of a frequency/duration timer (especially when the flow rate processed is constant and when extracted sludge concentration is of little consequence);

- in proportion to the flow rate (modulating the frequency of constant duration extractions);

- based on sludge concentration (measured using an ultrasonic probe or assessed by measuring the scraping force); measuring the maximum sludge blanket level is then recommended;

- from the sludge level in the clarifier (detected by ultrasonic probe or optical sensor).

scum

In most cases, matter floating on the surface must be separated from sludge. Usually, this floating matter is routed by a surface skimmer to a hopper or a trough that leads to the pit where the sludge is concentrated. The use of automatic connection pipe cleaning mechanisms is often recommended.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later