introduction

Reading time:Even when dewatered, sludge often presents specific problems; unlike past times, they can no longer be regarded as ultimate waste that can be used for agricultural spreading or that can immediately be disposed of at a landfill site (see section sludge end uses).

This sludge contains organic matter that gives it a potential agricultural or energy use. This potential is balanced by the presence of a range of pollutants ranging from bacteria, through all the heavy metals, to dioxins. There is a permanent fine line between the recycling and direct elimination options on the one hand and regulations and economic limitations associated with recycling and disposal costs on the other.

Sludge processing using the heat process is comparable to chemical or pyrometallurgical industries and raises the problem of industrial discharge.

Liquid sludge, even after thickening, contains very little dry solids content (4-8 %). Heat processes applied to this sludge have two different end purposes: either acting as an accelerator for biological processes (thermophilic anaerobic digestion, pasteurisation – see chapter Liquid sludge treatment), or responsible for thorough oxidisation of organic matter (wet oxidation, see section organic matter destruction using the wet oxidation method).

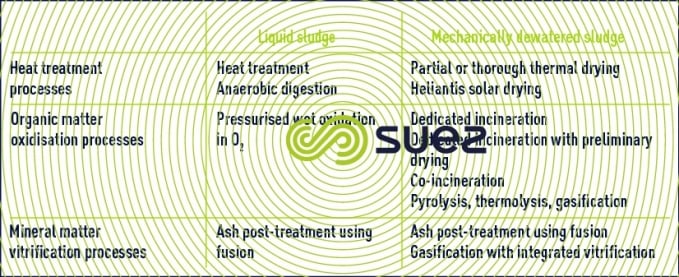

Mechanically dewatered sludge has a considerable dry solids content (16-35 %). Heat processes applied to this sludge have three different end purposes: these processes are either used purely for thermal dewatering (partial or thorough drying) or for the partial or total oxidation of organic matter without affecting mineral matter (incineration, gasification, thermolysis, pyrolysis) or as a thorough heat treatment carried out on the mineral content of sludge accompanied by mineralogical modification (vitrification).

Table 2 provides an initial classification of heat processes applied to sludge.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later