drying unit design

Reading time:If the drying technology selection is an essential issue, the drying unit’s overall design is even more important because its overall success depends on sound engineering of peripheral equipment.

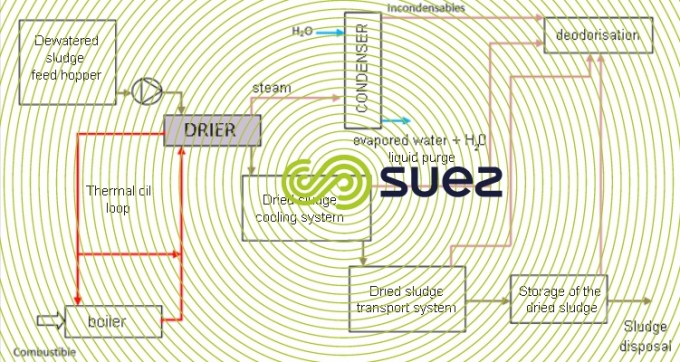

The drying unit comprises the following main items of peripheral equipment :

- wet sludge and then dry sludge handling facilities;

- heat exchange fluid loop;

- vapour treatment with or without heat recovery;

- dried sludge post-treatment if required; pelletisation;

- drying unit ventilation

- dry product long-term storage;

- drying unit overall safety. (see section safety and drying units).

The overall availability of a drying unit depends, therefore, on not only the dryer but all of the peripheral equipment too.

This design must be managed in great detail. In the remainder of this chapter, only general points will be discussed.

dewatered sludge handling systems

Preference must be given to pumping, carefully distinguishing between the areas in which eccentric rotor pumps or piston pumps should be used (see section hydraulic piston press – the dehydris twist workshop). Sludge delivered by a filter press must first be crushed.

When the drying unit is not part of a wastewater treatment plant and when this drying unit is required to process sludge from different sources, delivered to the site after a period of storage and transport, we strongly recommend that the handling equipment be preceded by a filter used to separate out foreign bodies and that the different reception facilities are organized to take sludge according to the latter’s dry solid content and intended end usage.

It should be noted that the rheology of dewatered sludge changes when stored (dewatered sludge management is flexible but drying operations are more difficult downstream).

cooling dried sludge

It is important to cool dried sludge before it is stored in order to limit risks in relation to self-heating. Some dryers produce dried sludge with a temperature low enough for it to be stored directly (e.g. Evaporis™ LE). However most thermal dryers require a dried sludge cooling system. The most commonly found system is the cooling screw conveyer system.

dried product handling systems

This is an essential stage because, quite often during the handling processes, the sludge’s granular structure can be damaged, at least in part. Handling is also a source of abrasion. Furthermore, this unit must be protected by stringent safety rules (see section safety and drying units).

Different types of dried sludge conveying systems exist :

- Screw conveyor,

- Tubular chain conveyor,

- Dense or a dilute phase pneumatic conveyor,

- Conveyor belts,

- Bucket conveyor

Bucket conveyors enable structural deterioration of the dried sludge to be reduced to a minimum.

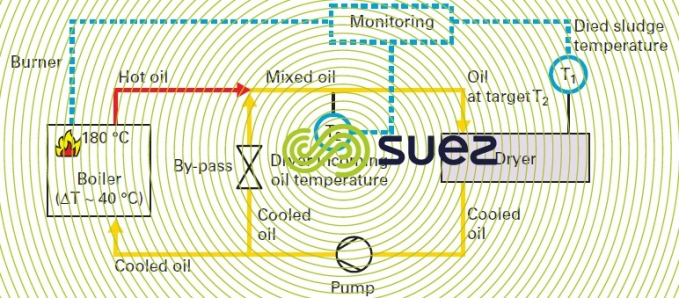

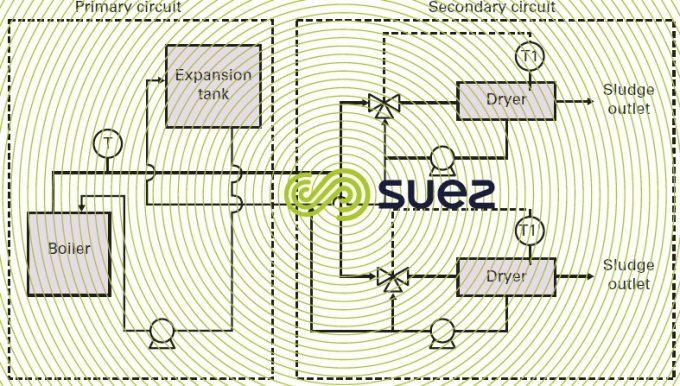

the heat exchange fluid loop

Figure 14 shows a thermal oil type heat exchanger fluid loop and figure 15 the case of a loop with a single boiler used for two dryers in parallel (e.g. Metz, Limay).

treatment steam

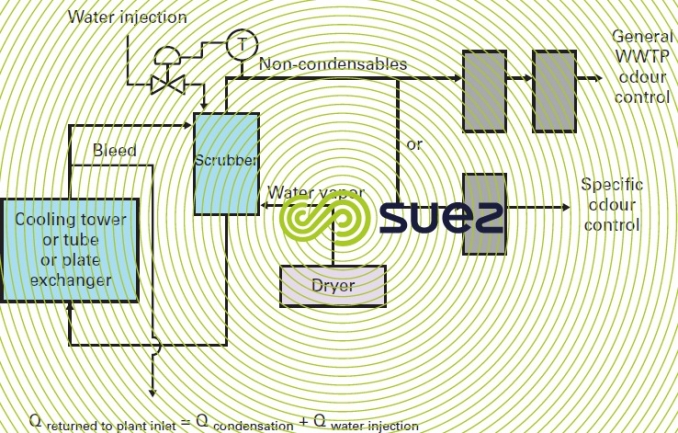

Steam generated during drying is condensed during cooling. Except in special cases where a drying platform is exterior to the wastewater treatment plant, condensates are sent back to the head of the plant.

Following odour removal treatment, specific or general to the plant, steam which cannot be condensed is released to the atmosphere.

Whether direct or indirect, some dryers have internal condensation systems allowing them to release steam which cannot be condensed at a low flow rate (such as Evaporis™ LE and Evaporis™ LT dryers). Quenching (condensation column) is however strongly recommended before odour removal treatment.

Other dryer technologies such as drum dryers (DDS Andritz), belt dryers or combined Vomm dryers condense steam using external condenser.

Condensation of gaseous effluent is generally carried out using water condensers :

- either by directly injecting cool water in large quantities (called "direct contact" condenser). This is the principal of a condensation column in an open circuit (water loss),

- or by a tubular condenser in which water circulates in a closed loop and is cooled in a cooling tower or by a cooling unit ("separated fluid" condenser or indirect exchange). This technique allows a certain smaller amount of water to be sent back to the head of the plant. In this case, it is possible to recover the available energy coming from latent heat resulting from steam condensation. The condenser water loop is closed by an exchanger which will produce a low calorie heat network (60-85°C) (Figure 16). The closed loop must include a deconcentration purge to be sent to the head of the loop.

Air condensers also exist. For example, this is they type of condenser found in the Evaporis™ LE unit between the 1st level, thin layer dryer and the 2nd level, belt dryer.

Whatever the condensation system used for a dryer's steam, the steam which cannot be condensed is extracted and sent for odour removal treatment. In the case of non-limed sludge, dried in an indirect dryer, the steam contains fine particles (3 to 5 g Nm-3) and volatile substances: VOC, NH3, H2S… The VOC are made up of aldehydes, ketones, amines, etc. The compounds may warrant the instalment of a purpose-designed odour removal unit.

condensate quality

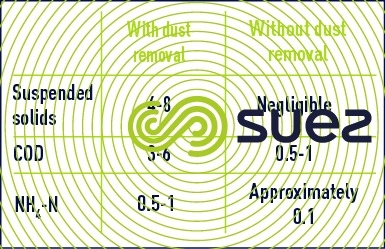

According to the desired temperature of condensate leaving the condenser, requirements in cold water to condense the gaseous effluent varies from between 10 m3 à 30 m3 of water per tonne of steam for an open loop condensation column. The higher the flow rate of cooling water required for condensation is, the lower the condensate's temperature is.

Therefore, condensate from thermal drying has a temperature of between 30 to 95°C. Its average temperature is around 60°C which means that at the most, the water in the gaseous effluent extracted from the dryer is condensed but without increasing to a maximum, the cold water's flow rate in order to reduce the flow rate returning to the beginning of the plant.

In plants, the quantity of water required for gaseous effluent condensation is easily obtained and can be returned to the head of the treatment facility, although it is necessary to take into account the extra pollution load.

The quality of condensate depends on:

- the type of dried sludge (biological, mixed, digested),

- The type of dryer used (retention time and operating temperature) => the lower the dryer's operating temperature is, the less the steam will be contaminated.

- the quality of cold water enabling condensation to take place (in general industrial water),

- the flow rate of cold water used for condensing.

formatting dried products : pelletisation

Drying processes will not always produce a sufficiently granulated end-product. This lack of self-granulating performance is linked to the process itself but also and above all to the nature of the sludge processed.

Feedback received has shown us that :

- a high VM content, wholly biological sludge will easily constitute granules;

- self-granulating properties decline gradually in the case of mixed sludge as the percentage of primary sludge increases;

- digestion has little impact on self-granulating properties;

- the level of fibres, mainly in primary sludge, deteriorates self-granulation. A critical level of 5% is normally accepted (this level is defined as the point when wet screening (500 µm mesh) categorically rejects dewatered sludge).

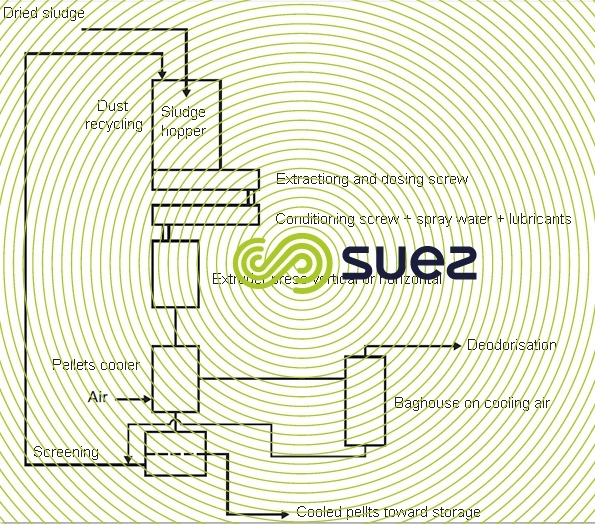

When a drying unit based on the self-granulation principle cannot be considered, the system will need to include a dried product formatting unit. Pelletisation is the most widespread technique. It consists in extruding the pre-dried product through a die. This die will have a 5 to 8 mm diameter. The extruded product is termed «pellets» (figure 17).

On grounds of safety, pellets must be cooled before final, long or short term storage. This cooling temperature must absolutely be lower than 40 °C, even 35 °C (see sectionAdsorption).

The pellets produced must undergo quality controls :

- particle size : the amount of fines is usually subject to severe limitations. «Fines» refers to the quantity of products below the strainer removal capacity applicable to the size of the system. As a rule, 2% is accepted as being the maximum amount of fines ;

- There is mainly a restriction on dust levels. It should be noted that specifications quote a 63 mm straining threshold with a weight level that must not exceed 0.1% of the product allowed through. We believe that this is not a realistically measurable level and, therefore, that it cannot be guaranteed. We recommend that dust be defined as products that pass at 300 µm and at a level that does not exceed 1%;

- hardness : in effect, this is resistance to compression measured using a standardized method called the Kahl test. Compression resistance must be better than 30 N;

- hardness (brittleness) : this is a standardized test called the Holmen test. The results produced by this test must be better than 90%.

If the pellet-making unit allows highly calibrated and dense pellets to be obtained (density of around 0.7), the equipment necessary for the pellet-making unit to function is difficult to operate and induces high operating costs.

Significant wear and tear of the equipment requires frequent renewal of parts and also results in a significant drop in the dryer unit's availability, due not only to when parts are exchanged but also to the numerous unscheduled shut-downs. Furthermore, a pellet-making unit means the introduction of ATEX equipment such as pellet cooling equipment as well as a bag filter for air cooling due to the movement of fine particles.

Following operational feedback it is strongly advised not to use pellet-making equipment with a thermal drying unit.

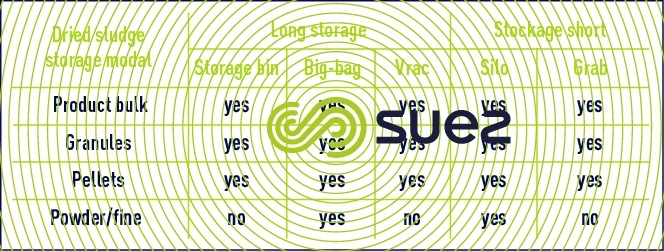

storing dried sludge

Depending upon the final dried sludge outlets (cement kiln plants, household EfW plants, composting, lands preading, etc.) the length of storage time can vary from several days (e.g. cement kilns) to several months (lands preading).

Different types of storage is therefore possible depending upon he storage time required, the storage space available as well as on the type of dried sludge obtained :

- Long-term storage

- Box (for medium to large amounts)

- In bulk (for medium to large amounts)

- Big-bag (for small to medium amounts)

- Short-term storage

- Open or closed Big-bags (for small to medium amounts)

- Silo (for medium to large amounts)

Whatever the type of storage, the temperature of the sludge entering storage must always be lower than 40°C, even 35°C for sludge identified as being "at risk" in order to limit risks related to sludge self-heating problems.

drying unit ventilation

A sludge drying unit, comprised of numerous peripheral equipment, must be sufficiently ventilated in order to remove the calories produced by the dryer, boiler and pipes.

Ventilation also enables to limit odours in certain zones at risk in the unit, such as liquid at the foot of the condensation column, open zones, etc, …

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later