coupons

Reading time:The most widely used method, coupons are test pieces cut out from the metal to be tested and having a known surface area and weight (after cleaning). The most significant exposure parameters are given below :

- water composition;

- temperature;

- fluid velocity along the entire test piece;

- metal surface condition (roughness-passivation …);

- exposure time.

The exposure time will always be a compromise between the lack of available time and the validity of the result. The rate of corrosion is often fast to begin with (bare metal) before slowing down to a constant rate when the various films are in place. Too little time will, therefore, produce excessively high rates. Therefore, coupons are typically put in place for 1 to 3 month periods. They may be submerged in the circuit or in a by-pass loop and will be mounted on a non-conducting base.

After exposure, the test pieces are cleaned and weighed to see how much weight they have lost (ΔP) expressed as layers lost (mm·year–1) using the equation.

where :

ΔP : weight loss (mg),

S : exposed surface (cm²),

ρ : metal density (g · cm–3),

Δt : exposure period (day).

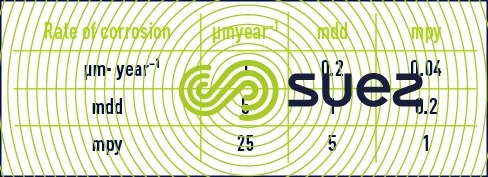

To express results using different units: mdd = mg · dm–2·day–1 or mpy (thousandth of an inch per year), use table 7.

In addition to being used for determining the average loss, test pieces must be examined to ascertain the type of corrosion involved and to establish, for instance, pitting depth (microscope examination to establish the depth reached), the nature of the products collected …

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later