cathodic protection

Reading time:Cathodic protection consists in applying an external electric potential to a structure. It is applied as follows :

- application of a potential and the resulting current from an external electrical source ;

- use of sacrificial metals such as magnesium, zinc or aluminium that are less noble than steel and that produce a protective galvanic current as the result of their selective dissolution.

This form of protection makes the metal structure entirely cathodic. The metal structure cannot be corroded while a sufficiently negative potential continues to be maintained so that the surface to be protected is wholly polarised and kept within the passivity zone.

The use of this protection can be considered :

- either in the presence of different electrolytes (more or less saline water, more or less humid soils) ;

- or when several metals come into contact with the same electrolyte.

The generally accepted criterion applicable to the cathodic protection of steel consists in applying potential levels (measured at the copper-CuSO4 electrode) of between – 0.85 and – 1.0 V. The current density will depend on the metal surface to be protected, e.g. :

- 60 mA · m–2 for a bare metal grating submerged in seawater;

- 5 mA · m–2 for an epoxy coated mechanical grating;

- 0.1 mA · m–2 for a pipe lined with epikote pitch or pipelines laid in a wet, not very conductive soil.

The earthing point formed by the anode is constructed using a non-corroding material (ferrosilicon or platinum-coated titanium) with current densities of approximately 0.1 A·dm–2 and 10 A·dm–2 of anodic surface respectively. The potential differentials applied will be from 5 to 10 V in freshwater and 1.5 to 2V in seawater.

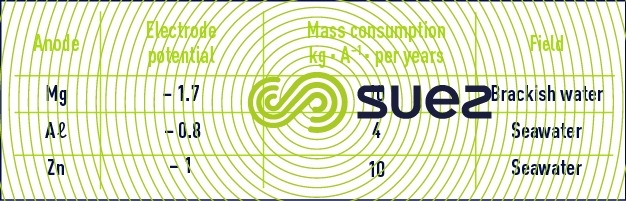

Sacrificial anodes (table 5) can be considered for use with submerged structures that have a simple geometry or when the use of other processes is restricted for mechanical reasons (e.g. scraped clarifier bridges).

Some practical considerations limit the use of cathodic protection: the use of excessively high potentials can result in the production of elementary hydrogen that embrittles the components, especially high strength alloys; the cathodic protection’s area of effectiveness will be limited accordingly: this area of effectiveness will be determined by the geometry of the equipment and by the water’s conductivity.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later