agri-food industries

Reading time:The agri-food sector is characterised by its diversity, size, the types of companies, the wide range of raw materials, products and processes used as well as the numerous combinations that it allows. The sector is also subject to diverse local economic, social and environmental conditions and subject to national or even regional regulations.

The most serious environmental impacts are water consumption and wastewater discharge and energy consumption.

The COD and BOD levels in agri-food effluent are usually high and may be as much as 10 to 100 times higher than those in domestic wastewater.

However significant, instantaneous daily (cleaning at the end of the day), weekly (cleaning at the end of the week) and seasonal (seasonal activity) polluting streams are one of the characteristics of this type of effluent.

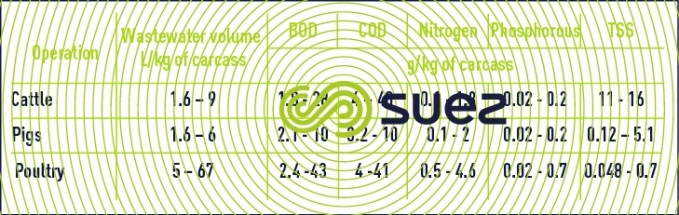

slaughter houses and the meat industry

The polluting streams generated by this industry depend firstly on the type of meat (cattle, pigs, sheep, poultry) and the processes found downstream to the slaughterhouse.

Tripe-gut dressing workshops and the draining of stercoral matter, present in the majority of the meat industries, discharge alone more than 50% of the pollution.

This depends on:

- the size of the tripe-gut dressing workshop in ungulate slaughterhouses. Stomach and intestinal washing may account for nearly 20% of the total BOD5 and 15% of nitrogen emissions and thereby significantly contribute to the organic content in effluent. Pathogens can also be found in rumens or intestines;

- the blood recovery rate (blood in a liquid state, COD: 400 g.Lˉ¹, BOD: 200 g.Lˉ¹, NK: 30 g.Lˉ¹). Amongst the liquid discharges generated by slaughterhouses, blood has the highest COD;

- side industries such as tanneries, salting and preserving use high quantities of salt (NaCℓ) leading to concentrations in chloride. The BOD5 load in these operations is around 10 to 20g per kg of finished product;

- the evaluation method for stercoral matter;

- fats, grease and oils (FOGs), present in high quantities.

The high SS content sometimes found corresponds to non-biodegradable fibrous cellulose matter.

Depending upon operations, the water used may be cold, hot (90°C) or in between (45°C). FOGs (mainly from ungulates from gutting and intestinal washing processes) which are present in large quantities are more or less emulsified depending on water temperature and the presence of surfactants (cleaning agents).

The presence of transformation operations: feathers (poultry) producing sulphides, blood or gelatine (pigs), which generate organic loads and SS.

In the face of environmental and energy challenges, industrials are forced to optimise their water consumption. Due to health requirements, water recycling may be limited to certain operations only.

tanneries and taweries

These workshops carry out routine skin pre-treatment involving soaking, liming in a lime bath containing sulphides and rinsing; the effluent can contain up to 3/4 of the pollution loading (riverside work unit).

The next treatment stage is tanning that can be carried out:

- in tanneries using plant tannins or mainly chromium salts which will be found in the ensuing discharges;

- in taweries using NaCℓ brine and alums (mainly mineral pollution).

evaluation of discharges

Volumes are highly variable:

- 20 to 120 m3·t–1 when chromium is used for tanning (2 to 3 kg Cr3+per tonne of hide) ;

- 20 to 90 m3·t–1 when using plant tannins;

- 200 to 250 kg COD and 75 to 150 kg SS per tonne of skins (approximately 30 kg for a bovine).

In the larger factories, the aim is to collect the following separately:

- preliminary treatment effluent;

- tanning vats (3 to 6 g . L–1 of Cr3+, pH 3,5) ;

- sulphurated alkaline water.

The discharge will contain protein colloids, grease, hair, colorants, chlorides and sulphides produced by the liming process.

glues and gelatine

In this industry, the raw materials are the skins supplied by the tanneries and the bones from the abattoirs that undergo acid solubilisation and alkaline hydrolysis in lime slurry; pig skins only undergo an acid wash before grease flotation.

The amount of wastewater can reach 60 to 70 m3·t–1 of bone and accounts for 50kg BOD5 per tonne of glue produced.

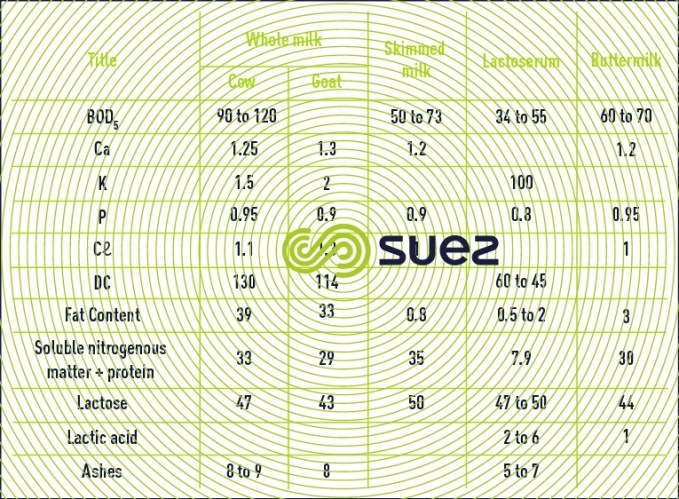

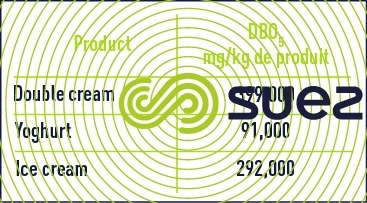

dairy industries

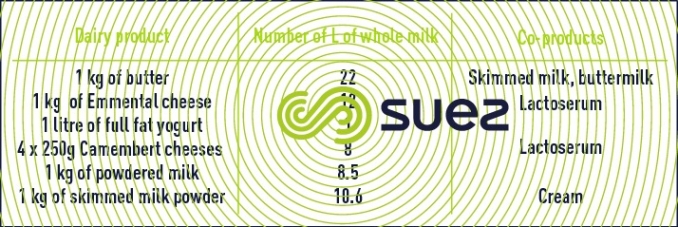

Dairy industries are generally integrated factories thereby manufacturing diverse products. Each product requires a certain quantity of input milk (table 41).

Origins of the discharges:

- pasteurisation and bagging: milk losses, diluted wash water having a very variable pH;

- cheese making and casein plant: whey from which protein has been removed but that is rich in lactose, is discharged;

- butter making: buttermilk, low in fat but rich in lactose and protein, is discharged;

- protein recovery through ultrafiltration;

- electrodialysis used for demineralisation and for recovering lactose from whey; reducing the pollution content in this discharge accordingly.

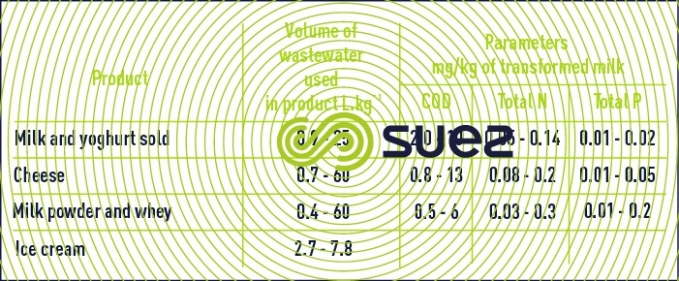

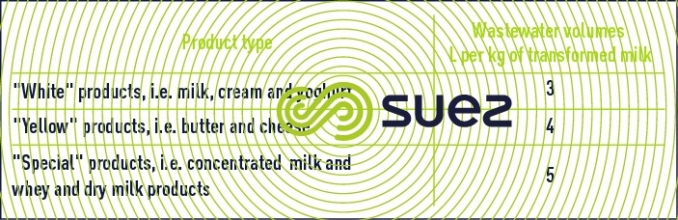

The manufacturing processes deployed on site as well as the type of product made are therefore at the origin of discharges.

The pollution load in effluents also depends on losses, which during milk transformation can be as high as 3 to 4% and, thereby, largely contribute to COD, nitrogen and phosphorus content.

evaluation of discharges

Dairy effluent is very easily biodegradable and this is shown by the COD/BOD5 ratio which varies between 1.5 to 2.

The recovery and the recycling of cooling water and condensates may easily be applicable given their low pollution load.

Cleaning operations are generally governed by automated programmes which include several boosted rinsing operations, either alkaline (soda) or acid in nature (phosphoric, nitric acid, etc.) This causes significant daily variations in pH, from 2 to 12, but also flow rate (cleaning at the end of the day, start-up of installations, etc.).

Their volume depends on recycling (cooling and condensate recovery), i.e. from 1 to 6 L.L-1 of treated milk.

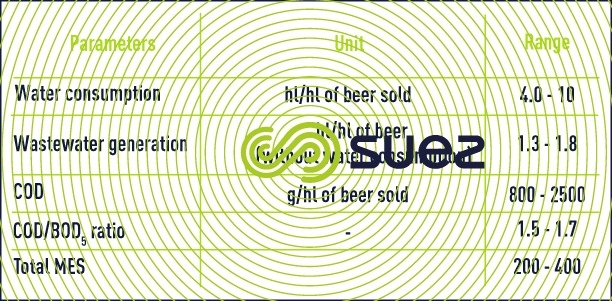

breweries

In beer-making and in terms of volume, water is the major raw material. The quality of this water is also a determining factor during brewing. For example, its saline composition directly affect the beer's characteristics (sweet, bitter, etc.).

Water which is in direct contact with the beer, yeast or various particles such as spent grains diatomite or diatomaceous earth requires treatment before being discharged.

Origins of the discharges:

- losses during bottle filling;

- cleaning (returned bottles, fermentation and conditioning tank vats, floors);

- filtering out the must and separating out cloudiness or yeast;

- draining out tank bottoms.

Evaluation of discharges:

- wastewater mainly comes from bottling and barrelling operations;

- fermentation and filtration processes can account for up to 97% of the total BOD load;

- pH varies due to the acidic and caustic chemicals used during cleaning;

- the TSS generated generally comes from by-product discharges and diatomite such as diatomaceous earth and sometimes label pulp;

- nitrogen mainly comes from malt, additives and detergents used for tank cleaning.

The ranges of concentration levels for various parameters is given below:

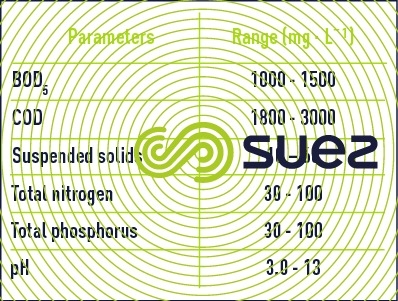

potato industries - starch manufacturing

Potatoes contain 12 to 20% starch, 70 to 80% of water and a lot of protein.

The different activities can correspond to the following operations:

- common: tuber washing and transport (soil and plant debris), sodium hydroxide or steam used for peeling (high concentrations of recoverable pulp and of starch and protein);

- specific: crisp and chip production (large amounts of fats), blanching (high BOD levels).

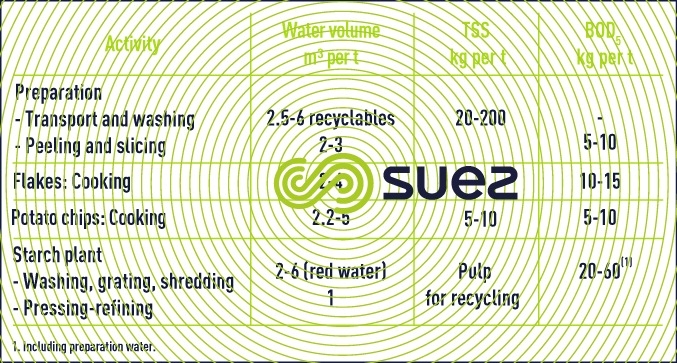

Table 48 gives typical values.

starch industries

Starch mills extract starch from manioc tubers and from potatoes. Wet method starch plants mainly extract starch from the richer cereals (wheat, rice, maize). In the latter case, pollution is generated by water evaporating and consists of volatile organic acids. When a glucose plant exists, it can generate pollution that contains high levels of soluble proteins.

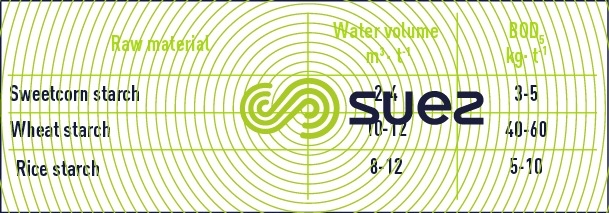

The nature of the effluent depends on specific raw material treatments that take place after a general wash (table 49, below).

Effluent characteristics:

- high amount of easily biodegradable organic matter;

- increase in the level of COD and BOD by hydrolysis and fermentation including reduced sugars, volatile acids and aldehydes;

- presence of nitrogen, urea and ammonia from compounds generated by the breakdown of proteins.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later