boosted sludge dewatering using piston press technology – Dehydris™ Twist

The Dehydris Twist based on proven Bucher Unipektin piston press technology, represents one of the most innovative and efficient systems on the dewatering market. It is fed with drinking water sludge or pre-thickened wastewater sludge conditioned with reagent.

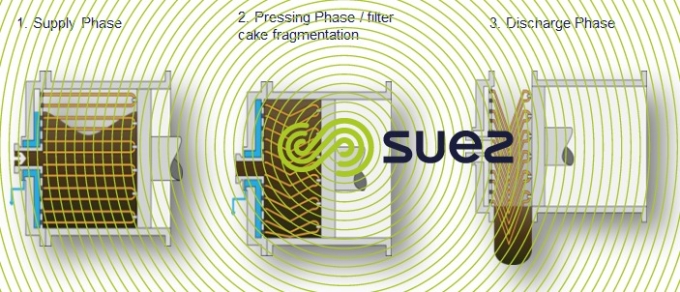

The press, equipped with semi-solid drainage elements, operates in cycles (from 2 to 3 hours). Each cycle is made is made up of 3 entirely automated phases: supply phase, pressing/filter cake fragmentation phase and discharge phase.

key figures

- Up to 30% in sludge bulk compared to conventional dewatering

- 100% automated process, including frame opening

among references

- Milan San Rocco (Italy) 1,000,000 PE

- Béziers (France) 200,000 PE

- Victoria Ville (Canada) – 90,000 PE

- Increased productivity with a possibility of non-stop operation (24/7) without the need of a staff presence

- Smaller foot print than a filter press in continuous operation (up to 20% optimization)

- High dry content obtained without addition of lime: up to 40% for drinking water sludge and auto thermicity achieved for urban wastewater sludge

- Accepts both drinking water and wastewater sludge(mixed sludge, fresh, digested, thickened or primary)

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later