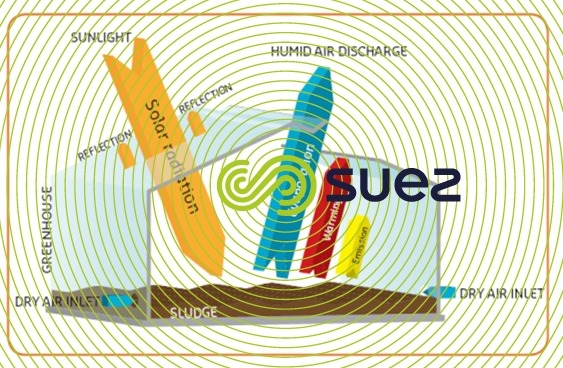

natural sludge drying in green house – Heliantis™

The HeliantisTMuses sun radiance to heat the surface of the sludge bed and aeration to evaporate the water contained in the sludge. The evaporated water then evacuated through natural convection, assisted by the ventilation system.

Upstream dewatering on DehydrisTM Twist allows the reduction of the sludge bed surface.

key figures

- Only 30 kWhe/t of evaporated water to obtain 80% of dryness at the end of the drying

- More than 50 references worldwide and more than 10 years of operation

among references

- Digne les Bains (France )– 35,000 PE

- Gargenville Issou (France) – 12,000 PE

- The sun, a free and sustainable energy source

- Smaller volumes. Savings in transporting and evacuating the sludge

- Long-term storage of the dried sludge

- Recovery/evacuation: a sustainable solution (agriculture, incineration, land filling, energy recovery in cement works or thermal plants, heating fuel, thermal plants)

- Final product is dry, granulated and easy to handle

- Fully automated sludge moving in the greenhouse

- Helps to reduce GHG emissions from the transport sector

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later