ozone generation

Reading time:Ozone is an unstable gas. Therefore, it is produced on site near the point of utilisation.

The overall reaction involved in ozone generation is endothermic (requires energy such as heat).

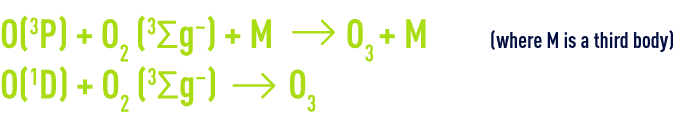

However the standard free energy of generation of + 161.3 kJ · mol–1 makes it impossible to generate ozone by thermal activation. Ozone synthesis involves the dissociation of molecular oxygen O2 in its fundamental state in the electronic configuration 3Σg– into O mono-atomic radicals in their fundamental state (triplet electronic configuration 3P) or excited (singlet electronic configuration 1D) state capable of reacting with oxygen.

The energy required to produce the O(3P) and O(1D) radicals from oxygen will rise respectively to 493.3 kJ · mol–1 and 682.8 kJ · mol–1. This energy can only be supplied by :

- a high voltage electrical discharge into the oxygen stream;

- electrolysing the water;

- photolysing the oxygen by irradiating it using UV at wavelength lower than 220 nm;

- using ionising irradiation to radiolyse the oxygen.

Irrespective of the process used, output efficiency will be restricted by phenomena involving the recombination of intermediate radicals and the breakdown of the ozone produced into oxygen.

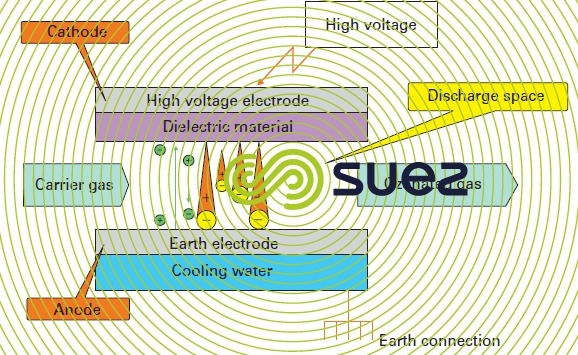

The only technique that will produce ozone at an industrial scale (> 2 kg ·h–1) consists of a corona electrical discharge into dry gas containing oxygen. The principle behind this technique consists in applying a 3 to 20 kV alternating potential differential between two electrodes where the gas circulates (figure 6).

As soon as a voltage is applied, the electrodes emitted at the cathode induce the ionisation and excitation of the species present in the gas. The electronic current will then increase through the combined effect of successive ionisations and secondary discharges triggered by the photons emitted by the species in a metastable or excited state. The avalanche of negative electrical charges produced is rapidly propagated towards the anode.

In addition to electrons, the medium produced contains species that are neutral and ionised in the excited state. This medium is termed cold plasma because of its electron concentration and of the latter’s temperature that is far lower than that of the molecules. At this stage in the discharge, enough electrons have acquired energy to dissociate the oxygen into radicals and to initiate ozone generation through recombination with oxygen molecules.

Therefore, it is suggested to limit the peak of the voltage applied and to alternate the voltage polarity applied at a sufficiently high frequency (usually 600 to 1,200 Hz termed medium frequency, “MF”) in order to avoid accelerating the concomitant stream of positively charged electrons towards the cathode and thus maintain corona discharge conditions. In order to prevent arcing conditions from occurring, the high tension metal electrode is coated with a high permittivity dielectric material (glass, ceramic).

The reference electrode is made of stainless steel. A tubular or plate system can be used. The industrial generator comprises :

- a series of individual systems that are assembled vertically or horizontally in a stainless steel casing;

- and its electricity power supply.

The greater part of the energy supplied is dissipated in the form of heat capable of breaking down the ozone produced in such a way that plasma temperature regulation becomes an essential factor in ozone generator performance. This requirement can be met in one of two ways :

- setting up a dielectric on one of the electrodes for distributing the discharge output over the entire electrode surface area, forcing the discharge energy stream to expand in the form of an extremely high number of cold plasma micro-discharges (temperatures of 30 to 50 °C above the average gas temperature). The dielectric material must have a breakdown voltage that is higher than the maximum peak voltage applied;

- the system is cooled in order to eliminate any surplus energy supplied (approximately 90 to 95 % of the energy supplied) by circulating controlled quality cold water, usually on the reference electrode side only.

The ozone generator can be fed with air or oxygen; however, all species present will be affected by electronic activation. Therefore, ozone generation will be accompanied by several simultaneous secondary reactions. The most important of these reactions are :

- the formation of nitrogen oxides, mainly N2O5 and N2O, created by the conversion of a small proportion of the nitrogen (up to 500 ppmV);

- HCs” hydrocarbons, especially methane CH4 and ethane C2H6, generated by air pollution, are comprehensively oxidised to produce H2O and CO2.

Therefore, it is extremely important for the carrier gas to be clean and dry :

- the presence of water vapor will have a direct effect on ozone generation performance and will also produce nitric acid from the nitrogen contained in the air. Nitric acid and water are deposited on the surface of the dielectric, making it a conductor. We recommend using a gas that has a dew point of less than. 65 °C at 1 bar absolute, i.e. air with a water vapor content of less than 5 ppmV. Air humidity is reduced either through compression and cooling, or through desiccation over an adsorbent material ;

- organic compounds such as hydrocarbons that are also harmful. Performance decreases linearly down to zero when the hydrocarbon content reaches 1 % by volume. The limit concentration in total hydrocarbons is set at 20 ppmV of equivalent CH4. This level is obtained by filtering the gas through granular activated carbon;

- when dust is present, this will also reduce the ozone generator’s performance. Filtration must be used to eliminate 99.9 % of particles measuring more than 1 μm.

On the other hand, when extremely pure oxygen is used as the carrier gas, it is advisable to add a little nitrogen (a few %) in order to improve ozone generation efficiency by initiating secondary avalanches, especially when high concentration ozone is required (6 % or more by weight).

Therefore, ozone production will depend on :

- the composition of the gas used (oxygen concentration, impurities);

- discharge characteristics (voltage, current frequency and, generally, the applied electrical power);

- gas temperature and pressure;

- the geometry and nature of the system (inter-electrode gaps of approximately 1 to 3 mm, electrode length and surface area, tube radii, dielectric constant).

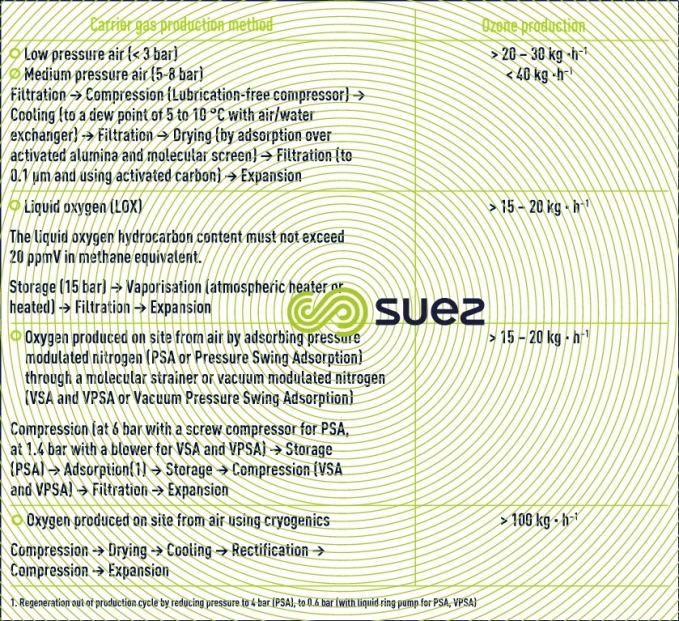

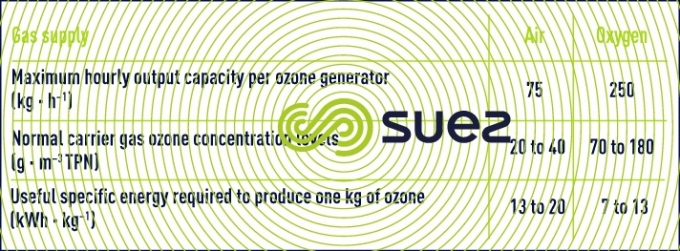

The gas supply system is selected according to the target ozone output, to the recycling options applicable to the oxygen that is not converted into ozone and to the costs associated with the various carrier gas production techniques (table 5).

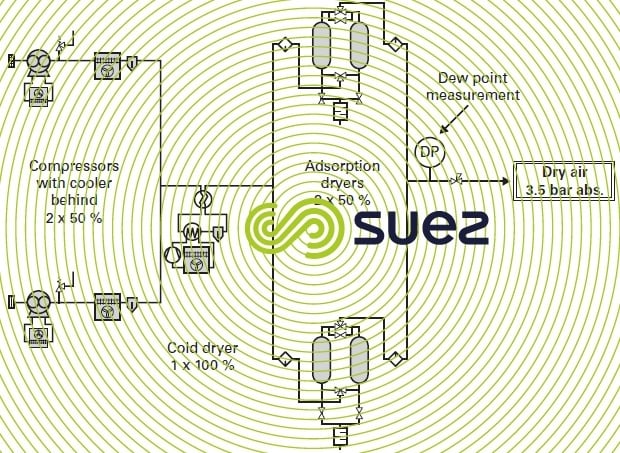

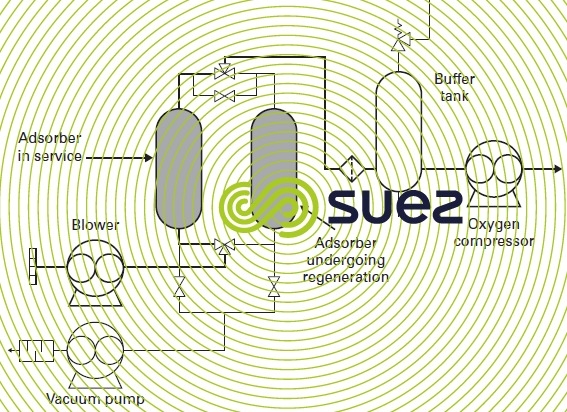

Figures 7 and 8 outline installation schemes applicable to the preparation of low pressure air supplies and to VPSA type oxygen production.

For each ozone generator, ozone production can be adjusted within specific limits set by carrier gas and dielectric material properties by altering the electricity supply’s voltage and frequency. Two main types of ozone generator are used in water treatment applications :

- air-fed, low frequency (50 or 60 Hz) ozone generators;

- air or oxygen-fed, medium frequency (60 to 1,000 Hz) ozone generators.

The voltage applied will decrease as the frequency increases and will vary depending on the constructor.

Table 6 is used to compare ozone generator performance based on carrier gas quality.

Once it has been generated, the ozone must be transferred to the water to be treated using the most effective diffusion system possible.

The production system includes the carrier gas procurement and preparation system, the ozone generator, the reactor and a system for destroying residual ozone gas.

The main technical characteristics of an ozone generator are:

- the ozone production capacity, variable depending on the nature of the carrier gas,

- the inlet pressure of the carrier gas, variable depending on the nature of the carrier gas,

- the cooling water requirements, variable depending on the desired temperature variation (in general, in the 5°C to 10°C range) and the nature of the carrier gas,

- the electrical energy requirements: high applied voltage (generally less than 5 kV effective), frequency and active power,

- the means of controlling ozone production, essentially by current variation.

Typical specific figures for (mains) electricity and cooling water consumption at a 20 °C temperature are:

- air as the carrier gas, 3 % ozone mass concentration:

- O2 as the carrier gas, 10 % ozone mass concentration:

The value of an O2 supply is obvious as soon as concentration and energy consumption become important criteria. the ozone production strongly depends on the ozone concentration and on the temperature of the cooling water. The variations are specific to each device.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later