reactors used in wastewater applications

Reading time:installation conditions

A pretreatment stage to UV disinfection is essential and with the exception of very diluted effluents, this pretreatment should include a biological treatmentand a tertiary treatment. The pretreatment level depends on the disinfection objective. (See residual suspended solids, transmittance…). In general, no disinfection will be considered when water transmittance is below 35% and when the suspended solids content is above 45 mg · L–1. Additionally, at this level of water quality only limited disinfection can be achieved (2 log inactivation maximum and effluent counts of 2,000 CF per 100 mL minimum). For standard disinfection objectives (3 log inactivation, 100 to 200 CF per 100 mL effluent counts), transmittance higher than 45% and less than 30 mg · L–1 in suspended solids are required. When stringent disinfection objectives are required, the water will have to be pretreated to provide a transmittance higher than 55% and less than 5 mg · L–1 suspended solids.

The presence of iron in the water to be disinfected needs to be investigated because iron can affect transmittance and above all the rate at which the quartz sleeves become fouled.

reactor types

Open reactors should be systematically used. The vertical orientation of the lamps means that access is extremely easy for the following components:

- the ballasts that are located in the module top enclosure (all electrical connections are above the water line );

- the lamps and quartz sleeves (it takes approximately 5 minutes to replace a lamp);

and thus an easy and rapid maintenance.

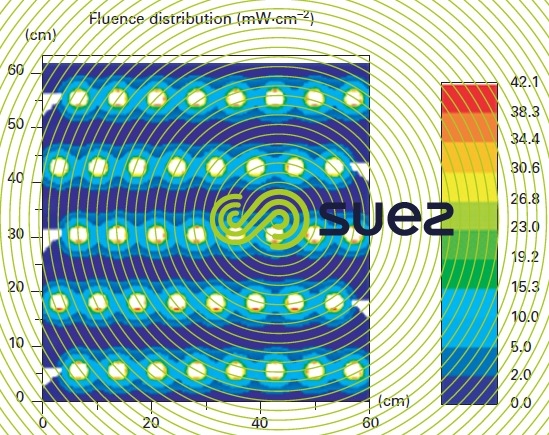

Recent improvements to lamps: changing from low pressure-low intensity lamps to low pressure-high intensity (HO) lamps (see table 14 the different types of UV sources) together with hydraulic improvements to the module frame (deflectors) (see figure 38 for the UVC flux distribution in a module of vertical lamps) have produced more compact units and spectacular cost savings.

Accordingly, the Windsor plant (photo 16), built in 1999, required 32 modules. In 2003, it would only have required 16 and in 2005, just 6 of the same geometry.

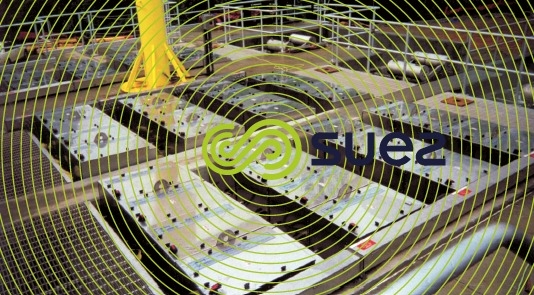

Picture 17 shows the disinfection system at the Camp Creek plant that uses 48 modules of low pressure-high intensity (HO) lamps arranged in three 4 x 4 module channels and clearly illustrates the potential compacity and simplicity of these plants. The ballast and lamp access hatches are visible at the top of the modules – with automatic shutdown when the lid is opened. At the top of the picture, the counterweight gate valves that prevent the lamps from being significantly uncovered, regardless of the flow passing through the channels.

cleaning systems

A quartz tube mechanical cleaning system is to be provided systematically (photo 18). This cleaning system should be complemented by an in situ chemical cleaning system operating at intervals that are specific to the application. The performance of the mechanical cleaning system can be improved by injection of pressurised air at the base of the module (photo 19).

level control

UV lamps must remain submerged in order to retain the longest possible useful arc length in the water and to avoid lamp overheating as this would cause the quartz tube to prematurely foul. There are three devices that can ensure that the liquid level remains within a given range: fixed weirs, adjustable weirs and counterweight gate valves.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later