general sludge treatment lines

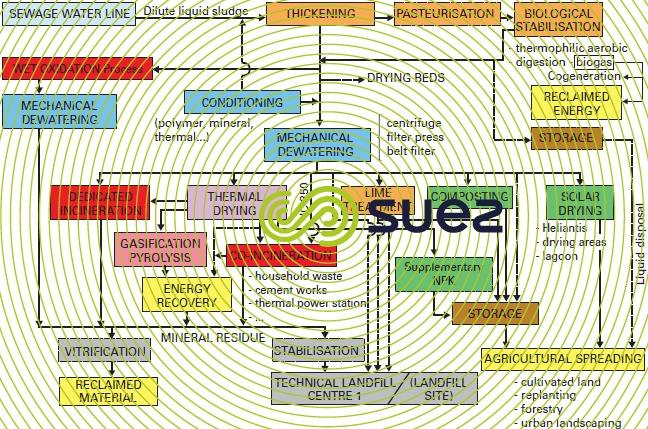

Reading time:Figure 1 illustrates the main stages that can be found in a sludge treatment process (solid line showing the most classic methods or those undergoing development, dotted lines referring to possible but less widely used methods or those that are being phased out).

In any case, two major objectives have to be fulfilled:

- reducing fermentation capacity (stabilization);

- reducing volumes (removal of water which is more or less bound with suspended solids).

Fermentation apacity can be reduced (see liquid sludge stabilisation) by:

- anaerobic digestion process (thermophilic or mesophilic);

- aerobic stabilisation process (thermophilic if it is to be properly effective, composting);

- chemical stabilisation process (post lime treatment carried out on the cake when a prolonged effect stabilisation is required);

- drying process (65-75 % dry solids content is sometimes enough depending on the sludge; however a higher dry solids content of 90 % is preferable);

- and, of course, incineration or co-incineration process as the final stage.

Volume can be reduced by:

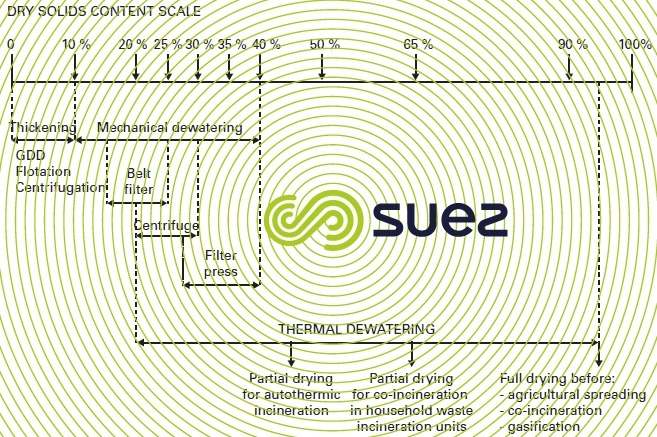

- more or less thorough thickening process (see sludge thickening). This stage becomes almost compulsory given the low sludge concentration levels obtained at the end of the water line (2 to 15 g suspended solids · L–1 in many cases). Following on from this stage, sludge will still be fluid (however, there are a few new processes that combine thickening and dewatering in one single phase):

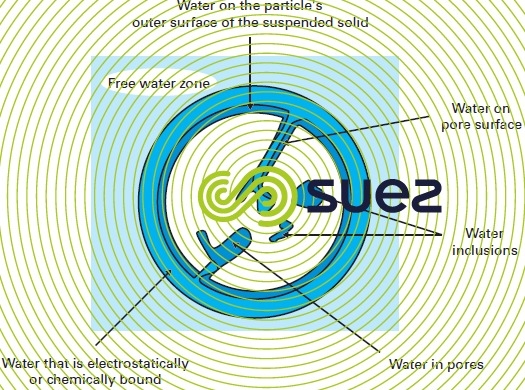

- mechanical dewatering process (filtration, centrifugation) dewatering (see belt filters, centrifugation, filter press). The energy levels used only allow us to extract what is called «free» water together with a small amount of water that is «bound» to suspended solids particles (figure 2). In most cases, mechanical dewatering of sludge requires pre-treatment:often by adding coagulation/flocculation reagents (mineral reagents or synthetic polymers) but also, occasionally, by means of heat (sludge conditioning);

- dewatering by heating process (solar drying, dryers using heat transfer fluids or gases). The energy used thus allows us to extract a large proportion or even all the water bound to the particles and, therefore, achieve high dry solids contents (figure 3 and drying).

- and, quite clearly, as the final stage, through more or less total incineration of the organic matter (incineration, pyrolysis, co-incineration, wet oxidation process… see thermal processes used to destroy the organic matter contained sludge and processes involving flue gas treatment downstream from the thermal processes).

Note: when thorough removal of pathogenic germs is a requirement (sanitisation), this can be achieved with some of the classic stages (two-phase anaerobic digestion, Naratherm drying for instance); however, specific stages will be required (pasteurisation, massive lime treatment, for instance).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later