screw presses

Reading time:These presses, able to develop high pressure, are applied exclusively to paper mill sludge and providing that this sludge contains more than 45-50% of fibres. Therefore, applications remain rare.

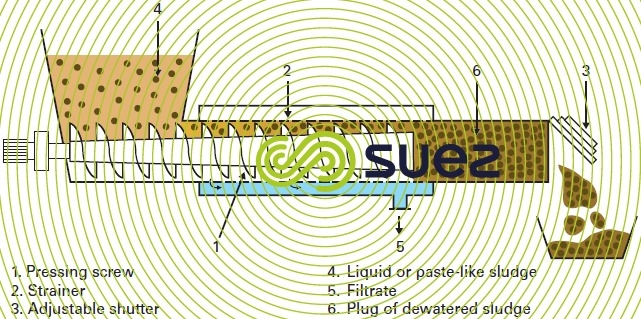

The screw press follows on from a draining step (e.g. GDD/GDE) thus feeding the press section with very thick sludge. The screw rotates slowly in a perforated cylinder, gradually compressing the sludge; this compression is made possible by a plug of dewatered sludge that forms at the screw outlet.

When the sludge is sufficiently fibrous, it produces 45-55% dry solids contents. Output ranges from 600 to1 000 kg suspended solids · h–1 for 600-650 mm diameter screws.

These screw presses can also be installed behind a belt filter in order to improve dry solids content by 10 to 15 points. These appliances require rather high maintenance (screw wear).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later