aerobic stabilisation

Reading time:aerated storage

Aerated storage must not be regarded as stabilisation treatment: its role solely consists in storing sludge over periods of up to several months, without creating any nuisance.

Aeration systems used in structures that are open to the atmosphere are either air diffusers (e.g. Vibrair, aerating pumps, jet aerator), or, increasingly rarely, surface aerators. In the long term, some systems can induce a certain mechanical destroying of biological floc, making its subsequent dewatering more problematic; the same systems create also higher heat losses. Injected air can also be used to mix and homogenise higher concentration sludge (potentially in excess of 30 g · L–1).

These storage tanks comprise one or more cells. In the latter case, the series arrangement of cells normally enables us to achieve a much higher and more homogenous stabilisation rate, with, nevertheless, low OM reductions (< 10%).

mesophilic aerobic stabilisation

In this case, the mineralisation rate achieved mainly depends on the quantity of O2 transferred, on residence time, on temperature and on the age of the incoming sludge. Therefore, aerobic stabilisation is not recommended in cold countries, unless special provisions are put in place: the reactor has to be insulated and covered over, heated if needs be. In the most frequently encountered climactic conditions, the OM level reduction in sludge produced by mesophilic aerobic stabilisation (<< 20%) remains very markedly below that achieved with anaerobic digestion.

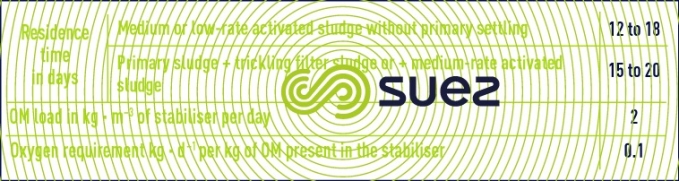

The following calculation bases (table 12) supplied for a temperature of 20°C, provide us with a rough guide to dimensioning.

Clearly, the oxygen transfer coefficient is low compared to that applicable to clear water, due to the liquor’s strong concentration. However, in most cases, the minimum mixing conditions define the aeration power that has to be installed.

25 to 45 % OM elimination efficiency levels can only be achieved in exchange for residence times and, especially, quantities of transferred oxygen that are very high (1 kg O2 per kg OM eliminated). However, these performance levels are more easily achieved in plants where thermophilic conditions can be sustained (sludge conditioning).

thermophilic aerobic digestion (or TAD )

This is a similar technique to the one used for composting solid organic waste (see heat treatment used on dewatered sludge – general comments). It capitalises on the exothermic nature of oxidation reactions in order to raise the temperature in the reactor (45 to 60°C); this temperature increase accelerates the reaction and, if sufficient, will produce a certain sanitisation. In order to obtain a sufficient temperature in the reactor, special provisions must be put in place to limit heat losses and, especially:

- have fresh sludge that has a minimum OM concentration (25 to 30 g · L–1) equivalent to a suspended solids concentration of approximately 35-40 g · L–1;

- limit heat losses caused by evaporation associated with the air saturated with humidity at the reactor outlet.

Specific submerged aerators (often combining the injection of air as fine bubbles and mechanical mixing) having high air diffusion efficiencies, reactors that are insulated and covered over, can be used to reach temperatures propitious to thermophilic organisms without any added heat.

It is difficult to optimise the size of a thermophilic aerobic digester. In effect, we have to reconcile the following (frequently opposing) interactions:

- the increased reactor capacity results in increased contact time but also in heat losses through radiation and evaporation;

- a high temperature gives rise to faster reaction kinetics but demands greater aeration power to overcome the oxygen’s lower solubility;

- a higher aeration energy use promotes oxygenation but generates higher heat losses.

In temperate climates, a 6 to 8 days residence time enables us to reach a temperature of approximately 50 °C in the reactor and a 40% elimination of OM from sludge having an initial DM concentration of 50 g · L–1 (including 35 g · L–1 of OM). In thermophilic aerobic digestion systems, special provisions need to be put in place to control foaming and the occasional emission of unpleasant odours.

Sludge discharged from a thermophilic aerobic digester operating at a temperature of 60 °C, has bacteria counts that are very much lower than those found in a mesophilic anaerobic digester. Ascaris eggs are difficult to detect and salmonellae and viruses are usually absent.

A certain number of treatment plants operate according to 60 °C thermophilic aerobic digestion system (1 or 2 days), followed by mesophilic anaerobic digestion that has been dimensioned for 80% of the amount of OM found in raw sludge. This combination does have some value if, at the first stage:

- advanced exothermic reactions make this combination thermally self-sufficient (whence the need to transfer enough oxygen to the liquor);

- the temperature level reached allows the sludge to be sanitised.

In practice, the problems encountered in sustaining aerobiosis conditions during the first stage frequently call for top-up heating. We then have development conditions applicable to hydrolytic and acidogenetic flora developed in thermophilic/mesophilic two-stage anaerobic digestion. The downstream anaerobic digestion system must, in any case, include normal sludge heating equipment (safety and start-up period).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later