final treatment plant

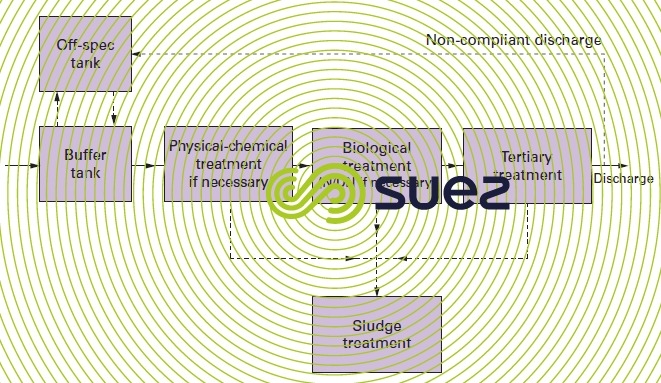

Reading time:The design of the final process water treatment system (figure 41) must:

- be capable of modification or expansion to adapt to changes in manufacturing processes;

- be as versatile and flexible as possible for the same reasons as above;

- be equipped with adequate equalisation and off-spec water storage tanks;

- be equipped with effectively positioned monitoring equipment (analysers, sensors, toxicometer…) in order to avoid any accidental or off-spec effluent that is unacceptable for process water usage or for discharge;

- ideally, monitor the pollution discharged by each unit and make operators accountable.

Note:

- if necessary, the equalisation can consist of several tanks that can operate in batch mode;

- the physical-chemical treatment is optional but may prove necessary when suspended solids are present or if there are metals to be precipitated, oils…;

- the need for tertiary treatment will depend on the discharge regulations, the available approaches being those described in tertiary treatment;

- thickening, dewatering;

- drying and/or incineration.

Given that chemical industry sludges, in general, are not suitable for agricultural spreading, the Biolysis process (see chapter Biological processes) is of particular interest because the cost of treating and disposing of sludge is an increasingly significant operating cost for chemical industries.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later