tertiary treatment

Reading time:The objectives of tertiary treatment, including the treatment processes below, can differ in nature:

- improving the quality of treated water in order to comply with discharge standards;

- reducing suspended solids and colloidal COD;

- phosphate removal (by precipitation with iron or aluminium salts, more rarely, using lime);

- reducing hard COD;

- colour removal, particularly in the case of textile industry effluents;

- removing specific compounds, e.g. pesticides, fungicides, metals, metalloids, AOX, detergents, soluble HC, nitrate and sulfonate derivatives, various anions…

It should be noted that, in the case of the last three processes, these are also used in specific pre-treatments. In effect, it is advisable to determine the treatment efficiency gained by the segregation of the waste streams, such as:

- small volume waste stream which is easier to process because concentration will be higher;

- or, on the other hand, to implement these treatments at tertiary level on all the combined effluent but after biological purification which usually helps to remove a portion of this pollution…

Quite obviously, this problem will only arise when the pollutants concerned have no toxic/inhibitory effect on the biological process.

- recycling treated water (in part or in full) to production units or, more often, to cooling towers, floor washing systems, fire water storage, even boiler feed systems. This recycling may require additional treatment to achieve the quality required. Finally, in some cases, the use of evaporation-crystallisation techniques (see evaporator-crystalliser) will allow no liquid waste discharge to the environment or “zero-liquid discharge”.

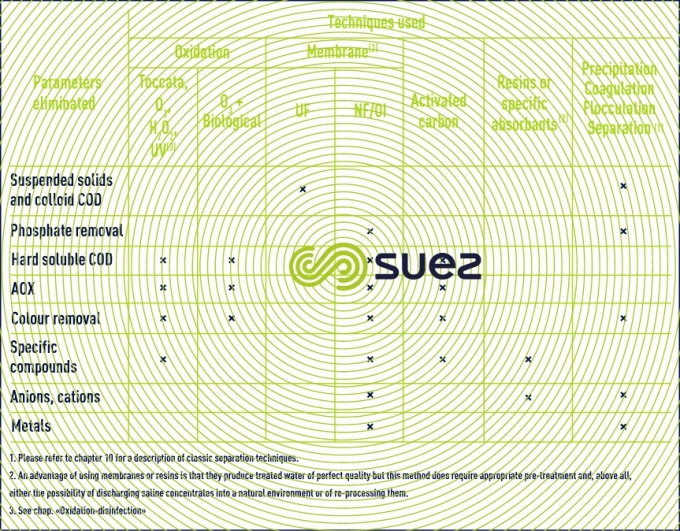

Please refer to table 1 for a summary of the various techniques that can be used.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later