other references

Reading time:Bel Evron

contexte, objectifs and needs

The BEL cheese factory located at Evron in Mayenne country, is a subsidiary of the BEL Group. It is part of the two biggest agri-food production sites in the county.

The effluent coming from the factory is biodegradable but contains fats which need to be taken into account in the biological treatment process design.

In addition, as the treatment facility is located a few kilometres away from the factory, is management must be autonomous.

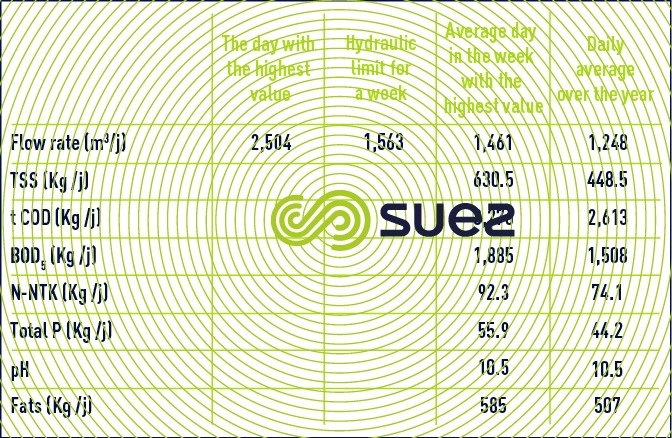

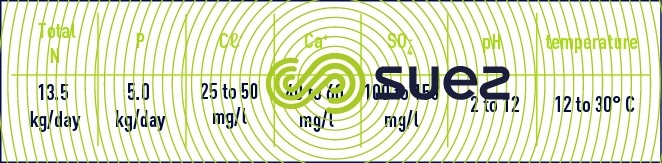

main characteristics of the effluent to be treated

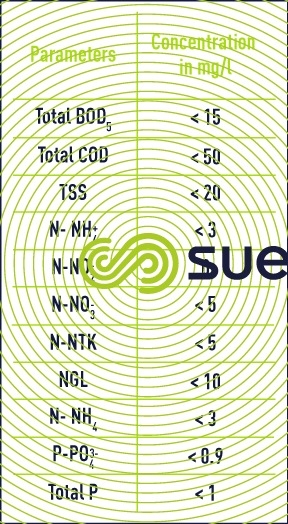

the main discharge standards

Following treatment the sludge’s dry content.will be 7%.

description and diagram of the facility

- screen and homogenisation tank

- buffer tank to cope with fluctuations in production and smooth flow rate over 7 days (low flow rate at the weekend)

- biological pretreatment to remove a portion of the BOD5 as well as taking into account olfactory nuisances.

- biological treatment for low pollution loads

- clarification of the mixed liquor through flotation enabling sludge to be concentrated and separated from treatment water and residual fats to retained.

- tertiary treatment using the Densadeg®,lamellar settling tank, with ferric chloride injection ensuring the treatment of phosphorus and the removal of additional residual COD present in its colloidal form as well as suspended solids.

- service water produced using treated water pumped at 10m3/h upstream to the metering channel. This allows different points of the plant to be supplied with service water, in particular :

- Secondary dilution of polymers.

- Thickening herse cleaning

- screen cleaning

sludge treatment including

- Sludge thickening using a drip screen.

- Liming

- Storage of thickened sludge in storage bags and a closed cylidrical-conical and odour-free.silo.

Candia (Vienne, France)

background, objectives and requirements

The project concerned the refurbishment of the new CANDIA wastewater treatment plant located in Vienne (France) and the operation of a 6-year contract.

The site's production has developed overtime and the plant designed in 1980 to treat effluent has become overloaded. To continue to be able to comply to discharge standards into the receiving body (River Rhône), it was necessary to extend the wastewater treatment plant.

CANDIA decided to entrust these works and the plant's operation to SUEZ, requesting maximum reuse of wastewater from existing plant facilities and equipment in order to optimise overall plant operation.

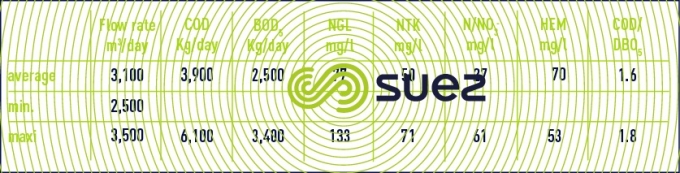

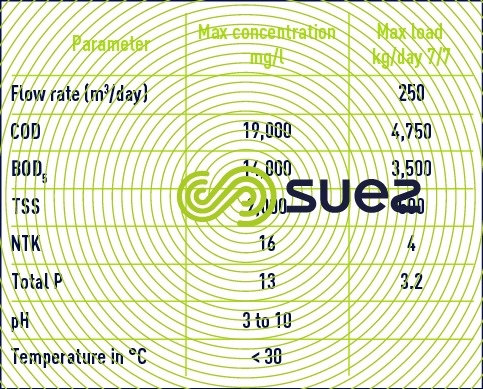

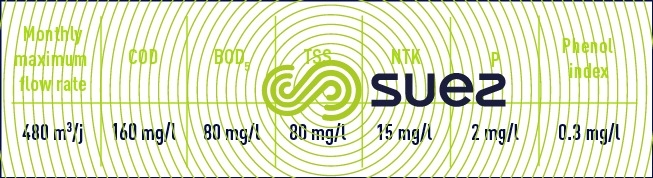

main characteristics of effluent to be treated and discharge standards

- Effluent loaded in FOGs and alkaline pH

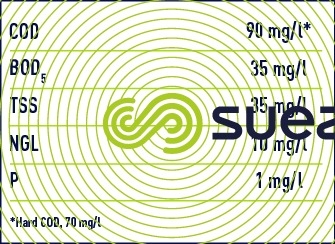

- Discharge standards

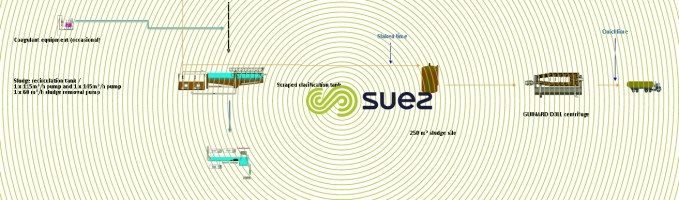

facility design

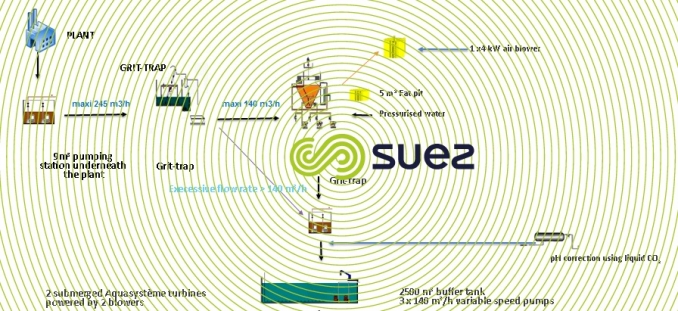

- a) pretreatment

- screening

- FOG removal: recovery of FOGs using floatation with white water then aerobic digestion

- grit removal

- 2,500 m3 aerated buffer tank with 2 blowers + bottom turbines (extension 2011)

- b) biological treatment

- bacterial bed

- high load aeration tank with injection of pure O2 (extension 2011)

- low load tank with 2 surface turbines

- c) final clarification and sludge treatment

- clarification tank

- sludge silo

- centrifuge

construction, commissioning, results obtained and client satisfaction

The refurbishment works lasted a little more than 6 months (buffer tank, pump, new electrical cabinets and PLCs and the creation of supervision system with remote control).

Commissioning was very quick with optimisation by using the targeted monitoring of the various treatment stages.

- The results obtained

Immediate positive effects :

- The buffer tank enabled the supply flow rate to be smoothed out, thereby avoiding water surges which could cause sludge to be pushed out the clarification tank.

- The increased volume of biological treatment with pure oxygen boosted the biological process resulting in excellent quality treated water, with high purification yields, in particular for COD (higher than 95%) and TSS, in keeping with the discharge quality standard objectives.

- The client was very satisfied :

- in terms of adherence to deadlines, budget and discharge standards

- with the implementation of treatment optimisation action plans andoperating costs.

CASTEL Frères - La Chapelle Heulin (44)

CASTEL Frères built a new bottling factory which required a WWTP with discharge of treated water into the surrouding environment.

characteristics of effluent to be treated

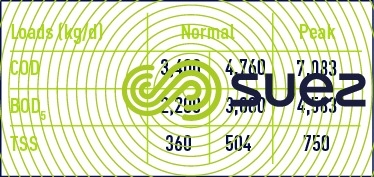

characteristics of effluents to be treated

plant sizing

- Pumping tank with sediment-trap filtration

- Fine 500µm curved screen

- 1,250 m3, covered, coated and sitrred buffer tank

- 750 m3 upflow anaerobic sludge blanket (UASB) unit

- BRMO with 1,000 m3 (vibrairs) aeration tank and 2 ZENON cassettes

- Centrifuge sludge treatment

the results obtained show a much higher discharge qualities than stipulated in the guarantees

- COD : 20 mg/l

- BOD5 : 3 mg/l

- TSS : 1 mg/l

- NGL : 1.5 mg/l

- Total P : 0,5 mg/l

the company Caves de Landiras

background, objectives and requirements

The company Caves de Landiras, located in Landiras (Gironde, France) has an outstanding production and packaging tool with 5 wine bottling lines.

Within a rationale of sustainable development and compliance to discharge standard, the company Caves de Landiras wanted to build an efficient wastewater treatment facility.

The quality of the effluent to be treated (concentration levels, characteristics and high biodegradability), resulted in a double stage anaerobic and aerobic treatment process to be implemented.

basic data and discharge standards

For a projected production of 900,000 hl the different type of effluent have the following characteristics.

- Flow rate = 480 m3/d

- Peak = 720 m3/d

The maximum authorised discharge standards are as follows :

facility description

The plant's treatment process includes the following main stages :

- Pumping and pretreatment (grit trap)

- Buffer tank with neutralisation and storm overflow tank (2 x 800 m3)

- UASB-type anaerobic digestion reactor

- Aerobic biological treatment (1,000 m3)

- Clarification tank

- Settling pong

- Sludge dewatering and storage in a skip.

results obtained and client satisfaction

Very high purification treatment yields : More than 98% of COD and TSS removed.

No non-compliances observed.

Results in average values.

Overall, the client is satisfied with the operation of the facility and the results obtained.

A few corrective measures have been undertaken concerning finishes during construction; the last observations made for certain coatings are being examined.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later