system organisation

Reading time:The cost of various treatment design options will largely depend on the organisational efficiency of the systems within the units and then on the scale of the plant.

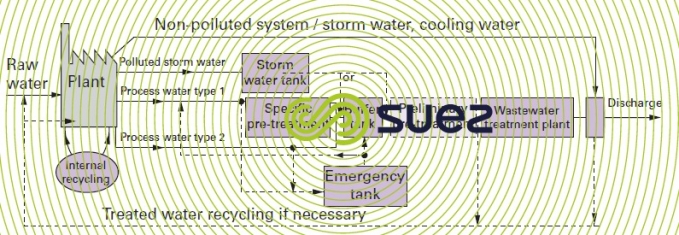

This organisation should be as close as possible to the scheme shown in figure 1, an “ideal” scenario generally providing the best technical-financial optimisation.

These systems include:

- recycling within the units with the objective of:

- recovering raw materials if desirable;

- reducing the wastewater volume to be treated;

- reducing water consumption;

separating discharges into:

- discontinuous discharge:

- polluted/unpolluted storm water;

- draining and wash waters…;

- polluted/unpolluted cooling water;

- continuous discharge:

- process water requiring specific pre-treatment;

- process water not requiring specific pre-treatment.

This segregation allows for the inclusion of storage or equalisation or effluent safety tanks:

- storm water tank that is normally empty and stores polluted storm water before it is returned to the processing plant at a regulated flow rate;

- buffer/equalisation tanks in units requiring specific pre-treatment;

- variable level equalisation tanks on the combined wastewater streams prior to treatment for the purpose to normalise flows and pollutant loads to be processed;

- effluent safety tank that is normally empty to store and ultimately treat or recycle non-compliant discharges to the head of the plant at a regulated flow rate after analysis have confirmed that this method is feasible without damaging downstream treatment(s).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later