chemical and semi-chemical pulp production

Reading time:This section includes chemical and semi-chemical pulps but not mechanical or thermo-mechanical pulp, with or without chemical additives, discussed under paper and cardboard manufacturing.

The wastewater produced by these industries is highly dependent on:

- the type of raw material used (hardwood, softwood, annual plants, etc.);

- the type of pulp produced (kraft, bi/monosulphite), Kappa index;

- bleaching sequences.

specific pre-treatment

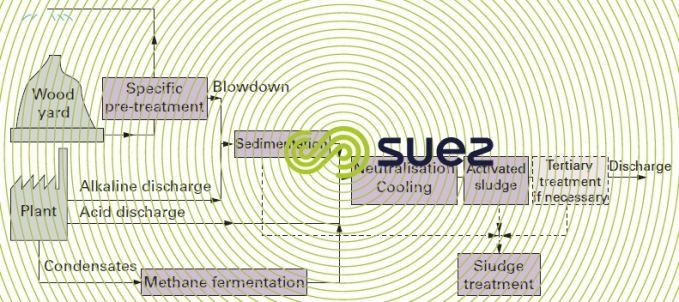

In general, some systems may require specific pre-treatment such as:

- sprinkling the wood yard: bar screening/straining, grit removal and then recycling;

- evaporation of condensates: methane fermentation;

- alkaline discharge with substantial suspended solids: sedimentation;

- acid discharge with lesser suspended solids: neutralisation.

biological treatment

This mixture of effluents is then cooled to 30-35°C before being treated using a biological process which usually consists of classic medium-load activated sludge.

Performance levels achieved with biological treatment are normally in the region of 95% of BOD5 and 50 to 80% of COD reduction, depending on the type of process and especially in the bleaching sequences used (raw water COD/BOD5 ratio varying from 2.5 to 4).

Note: TCF or ECF type outputs (see paper mills and the paper pulp industries) produce more easily biodegradable effluent because it contains less or no lignin chlorine derivatives.

As the bleaching cycle increasingly uses a pure O2, it is of interest to also consider using pure O2 in the activated sludge because of the following advantages:

- improved performances (COD, AOX…);

- improved sludge sedimentation capacity;

- compactness (higher load).

tertiary treatment

As in the case of paper and cardboard mills, supplementary treatment may prove necessary, especially with respect to reducing:

- suspended solids;

- hard and colloidal COD;

- colour;

- AOX.

The techniques described in tertiary treatment apply and the most efficient process design will depend on the specific objectives.

sludge treatment

When the plant is equipped with a bark boiler, this boiler will also incinerate dewatered sludge from the wastewater treatment plant.

When the plant does not have this boiler, all the treatment techniques described in chapter Dewatered sludge treatment will apply. The choice will depend on overall sludge composition and on its potential end use.

odour control

A partially covered unit combined with odour control may prove necessary when stringent regulations apply.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later