water treatment applications

Reading time:separating oily suspensions with low suspended solids content

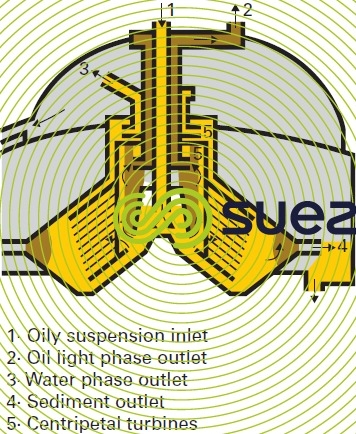

In this case, the industrial machines used are called disc centrifuges (figure 44).

These are vertical shaft, rotating machines that are capable for creating very high centrifugal fields (3,000 to 8,000 g). These units can be used with two sediment extraction systems:

- continuous output through nozzles (Ø 1 to 2 mm in diameter ): the effluent must not contain too much suspended solids (sediment volume below 2-3%) and especially no coarse particles (fine screening is essential);

- intermittent output via the restricted opening of the entire lower chamber (these machines are called: autocleaner bowl machines). They can process oily suspensions that have a higher suspended solids content (up to 5 or 6% sediment volume) but at moderate throughput rates.

Setting these clarifiers can sometimes be quite a delicate matter when the effluent quality (oil content) fluctuates. In effect, the financial appeal of this process depends on recycling the oils recovered so that they can be re-used; therefore, we need both an oil that does not have an aqueous phase and also an aqueous phase that does not have a very high oil content (maximum recovery).

This system finds its most widespread application in the treatment of wastewater produced by the automotive industry (soluble oils), steel mills, agri-food industries…

separating sludge-laden suspensions that have a high oil content

When the amount of sediment becomes too great (6-15% by volume), we can use 3-phase, horizontal shaft, cylindrical-conical continuous clarifiers: solid/water/oil.

Preheating up to 90°C and an appropriate treatment may often be required.

Separation reliability and regularity can only be ensured when these suspensions have relatively stable physical-chemical properties.

It should be noted that constructors are now developing machines that have a liquid ring that can be modified while the machine is running, thereby making oil/water recovery easily adjustable.

Applications: refineries, for instance.

cycloning used to separate out high granulometry, heavy particles

Cycloning also uses the centrifugal effect induced as the liquid arrives at a tangent into a fixed cylindrical-conical chamber. Acceleration levels are low but enough for separating out dense, granular particles (see section hydrocyclone).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later